- Joined

- Jul 5, 2013

- Messages

- 1,109

- Reaction score

- 624

- Location

- Jonesborough, TN

- My Car

- 1973 Mustang Mach 1

Well, since my 73 Coupe burned, I've been working on getting another project. I was able to find a 73 Mach 1, and last weekend, my wife and I drove to eastern Tennessee and picked it up.

Yesterday, I was able to clean it out, and vacuum the trash from the floor to see just what I have. Well, I have a lot of work ahead of me, it what I have. The core support is bent and needs to be replaced.

The front right inner fender is rusted through under the battery tray.

It has frame mounts welded in for an unidentified type of motor, and I discovered today that the center section of the engine crossmember was cut out and modified. When I removed the front bumper, I found the front left mounting hole was bent and torn, and the capture nut for therear bolt for that bumber bracket is not longer captured.

The cowl appears to be okay. That is, until I poured some water into the vents on top and discovered water pouring into the passenger toekick.

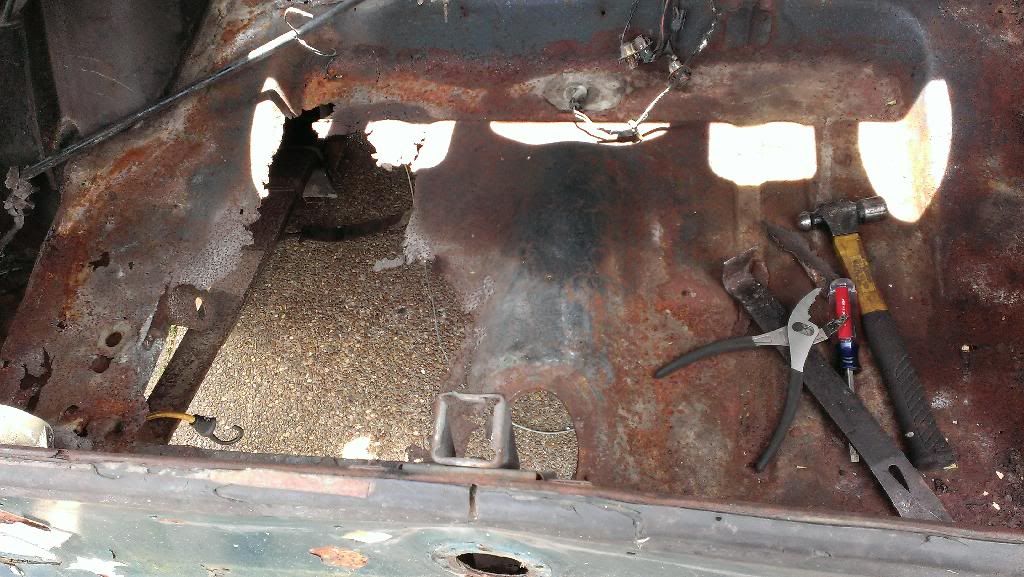

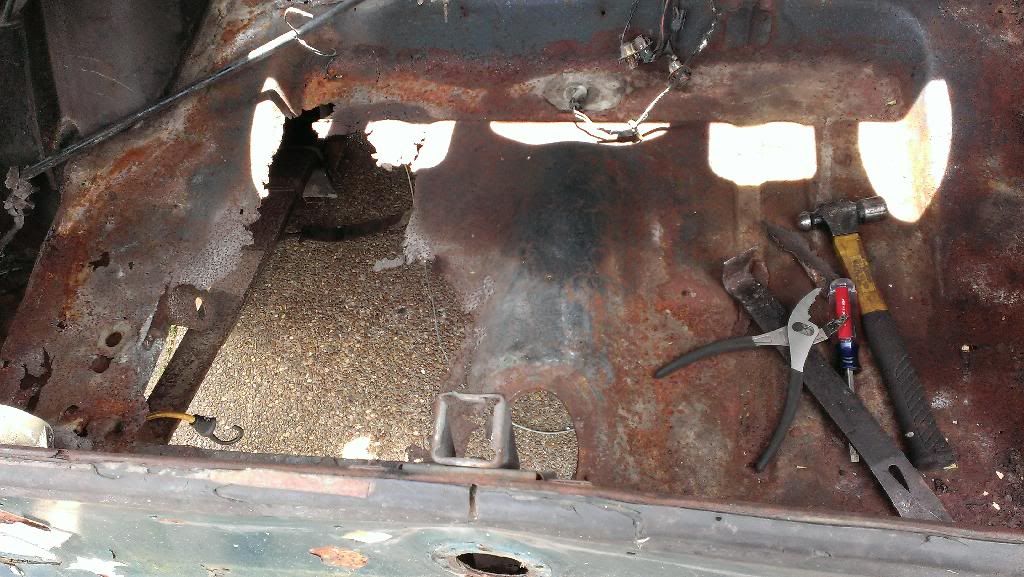

The left and right side floors need to be replaced, along with both front extensions. In the back seat area, both sides also have a bunch of rust that was partially covered with fiberglass.

The trunk floor was covered with a sheet of galvanized sheet, that when removed, revealed about 1/2 of the trunk floor rusted out.

The trunk floor extensions, outer wheel houses, and both rear quarter panels also have significant rust and need to be replaced.

The taillight panel also was extensively rusted.

Both quarters are rusted, and the passenger side has about over 1/2 of Bondo where it was seriously caved in.

The passenger door bottom is completely rotten. I haven't taken the drivers side door off yet, but I did see a little bit of rust on the rear corners, sooo....

So now you've met my new Mach 1 project. I'm calling it Rusty, a name that really seems to fit it at this point. I've really got a lot of work ahead of me. I'm thinking a road trip to visit Don at OMS may be in my future.

Yesterday, I was able to clean it out, and vacuum the trash from the floor to see just what I have. Well, I have a lot of work ahead of me, it what I have. The core support is bent and needs to be replaced.

The front right inner fender is rusted through under the battery tray.

It has frame mounts welded in for an unidentified type of motor, and I discovered today that the center section of the engine crossmember was cut out and modified. When I removed the front bumper, I found the front left mounting hole was bent and torn, and the capture nut for therear bolt for that bumber bracket is not longer captured.

The cowl appears to be okay. That is, until I poured some water into the vents on top and discovered water pouring into the passenger toekick.

The left and right side floors need to be replaced, along with both front extensions. In the back seat area, both sides also have a bunch of rust that was partially covered with fiberglass.

The trunk floor was covered with a sheet of galvanized sheet, that when removed, revealed about 1/2 of the trunk floor rusted out.

The trunk floor extensions, outer wheel houses, and both rear quarter panels also have significant rust and need to be replaced.

The taillight panel also was extensively rusted.

Both quarters are rusted, and the passenger side has about over 1/2 of Bondo where it was seriously caved in.

The passenger door bottom is completely rotten. I haven't taken the drivers side door off yet, but I did see a little bit of rust on the rear corners, sooo....

So now you've met my new Mach 1 project. I'm calling it Rusty, a name that really seems to fit it at this point. I've really got a lot of work ahead of me. I'm thinking a road trip to visit Don at OMS may be in my future.

Last edited by a moderator: