- Joined

- Sep 12, 2015

- Messages

- 8,072

- Reaction score

- 3,177

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

Today's update.

Well, it was finally warm enough outside to start cleaning and prepping the axle for paint. As with the rest of this car, no rust to speak of, just some light surface stuff that easily came off with a wire brush in a drill. Took all of an hour to do the whole thing. Once clean, I use a product we have in Canada called Dominion Sure Seal Rust Converter, which is a converter and primer. I used this more for the primer quality the to stop rust. Once that had dried, I was able to get a first coat of Eastwood Chassis Black over it all except the center section that of course will be red oxide primer. There is still some work to do another day to finish it off. Once done, I'll install the new brakes and get it back in the car, hoping the rear springs I got de-arched, will be okay. (if you read my other post on the GTA springs, you'll know why I say "hoping").

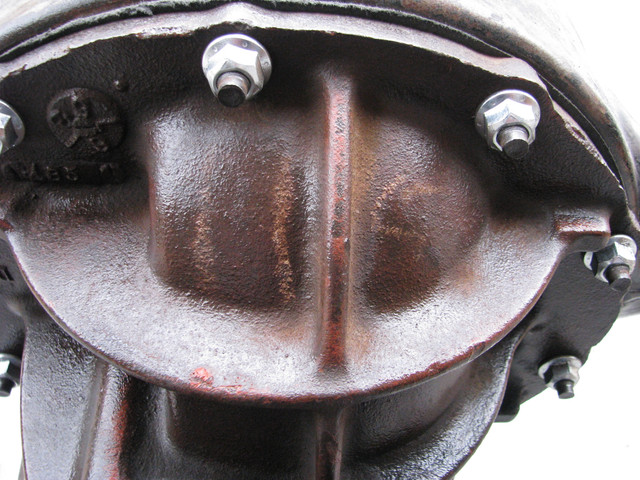

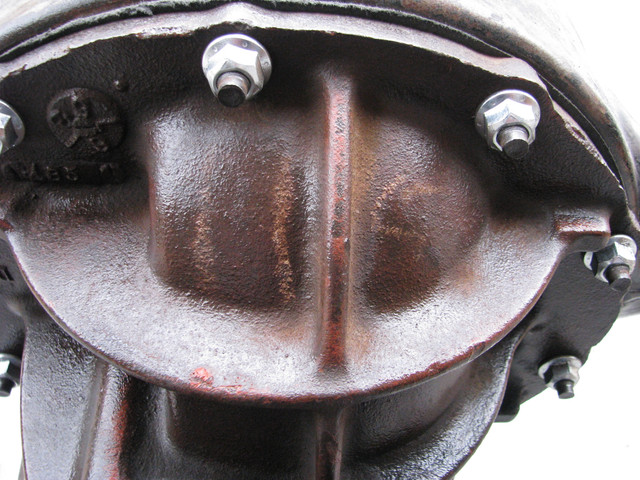

Anyway, I did find some paint markings on the bottom of the case as well as some on the center section. Unfortunately, they are not very clear or readable, so here's a couple of pictures hoping someone might be able to have a better guess as to what they are. The case ones appear to be 62 and possible 91, but the 9 and the 1 are sort of joined together at the bottom of the 9 and 1, so just a guess. The one on the center section appear to be 11 and 5 or maybe 6. The tag was unfortunately missing from this axle as it was evident it had be apart at some point for major service work.

Maybe a date 11/5 (70) Car is a Feb 71.

Any thought, please post them.

Well, it was finally warm enough outside to start cleaning and prepping the axle for paint. As with the rest of this car, no rust to speak of, just some light surface stuff that easily came off with a wire brush in a drill. Took all of an hour to do the whole thing. Once clean, I use a product we have in Canada called Dominion Sure Seal Rust Converter, which is a converter and primer. I used this more for the primer quality the to stop rust. Once that had dried, I was able to get a first coat of Eastwood Chassis Black over it all except the center section that of course will be red oxide primer. There is still some work to do another day to finish it off. Once done, I'll install the new brakes and get it back in the car, hoping the rear springs I got de-arched, will be okay. (if you read my other post on the GTA springs, you'll know why I say "hoping").

Anyway, I did find some paint markings on the bottom of the case as well as some on the center section. Unfortunately, they are not very clear or readable, so here's a couple of pictures hoping someone might be able to have a better guess as to what they are. The case ones appear to be 62 and possible 91, but the 9 and the 1 are sort of joined together at the bottom of the 9 and 1, so just a guess. The one on the center section appear to be 11 and 5 or maybe 6. The tag was unfortunately missing from this axle as it was evident it had be apart at some point for major service work.

Maybe a date 11/5 (70) Car is a Feb 71.

Any thought, please post them.