@Randy

Ahahaha, well, unlike US cars where you need search far away land, I've located some place in Germany with OE parts for lots less than via BMW/Mini channel over here (when I say lots less, I mean LOTS less), and have a primed + chromed bumper underway for 80 buxx. Been to my painter this week, got my green mixed for the 73 and the silver paint for the mini. The bumper should be here by Monday, so I should be able to spray it somewhere next week if weather permits. Then I'll need find time somehow to remove the old one and install it...

------------------------------------------

20% chances of rain said the weather app...

I was just installed and ready to get to the next step on the fender... poof, the 20% came down

As I can't go further on this baby, can't work on the 73 either. Went pick my next patient: The transmission shaft/ drive shaft. I've removed it a couple of weeks ago and needs to be done anyway. Just like many original parts on this car, it's all in its juice. Totally no play on both u-joints, aside the corrosion, it could be reused as is and there would be no problems. But I see its return on the car one day in another state

Started by spraying lots of penetrating oil and removing the lock clips. Two of them were not happy to leave their rusty grooves, so had to get them free by first ticking them so they'd turn a bit before get them out with pliers.

Then after a good quick clean up and again penetrating oil, the rear u-joint removal was next.

Often ignored in maintenance, these are in 99% of cases the reason why you get a "klunk", often from going front to back gear or if light, a droning sound and/or vibes when the car reaches a certain speed...

So for those with vibs and klunks, here's how it goes to remove them. If unlike mine your car got new one since 71, it should go even more easy.

At first sight, it looks like a puzzle: how the hell do you remove these??? The trick is, once the clips are out, to push from one side for say 0.5 inch/1.5 cm. Doing this in a big vice is super easy, but mine being too small and even partly broken (need order a new one yesterday), I've used a 19mm socket to push (fits the hole perfectly) and a larger one so the other side could go inside the socket. Once out, you can remove one of the covers/cups acting as bearings. Try keep these up while doing it. This give you enough play to remove the u-joint.

Then did the yoke side. Because mine were corroded and in there since 71. My "press" wasn't strong enough to get some movement. So had to use a big hammer to unseal them. Placed on hard surface, in my case blocks of iron, and level , it's all about give them that tick that will free them. No need to slam like an ogre (even if the hammer i've used looks like an ogre hammer), but its not made of crystal either. Just a good tick, and with the penetrating oil added before they should not resist. Both articulations needed a tick on mine. Removal was same as the above, pressed out with my sockets. Once they are free and there is oil, not much force is required.

I plan to replace the u-joints, but kept them as they'd only need a good clean and grease to be as new again in case I would not find the ones I need. For now, they went in a box...

The yoke, is in ok condition, but showing some corrosion on the shaft. As these go inside the trans and are in contact with seals, they have to be smooth as baby butts to the touch, so started by removing the raw rust with 80 grid, slowly and finished gradually up to 400. Then after a good clean and brushing, it went 15 minutes in de-rust bath, then soda bathed, and after good rinse, few secs of hydrochloric acid to etch the surface for plating. At this point the metal was pristine and ready to enter my zinc bath.

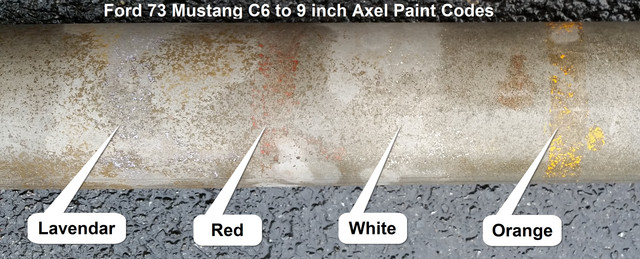

While the yoke was enjoying a 3.5- 4 volts bath (the voltage I find giving me best results for zinc), went busy on the big shaft. Man that thing is big, Peterbilt sized!! Much bigger than my 73 351/fmx one. Aside red paint applied on both extremities, only a long blue stripes was found. For the rest, looks like Ford did not apply anything on it. If they did, it's gone long ago, and entire shaft was under a layer of rust, but not pitted as it was very greasy, probably so for years. It didn't took me long to get it to bare metal and I'll de-rust it tomorrow further in phosphoric acid for a durable removal before paint it. I'll have to spot weld one of the weight that got loose when I've wheel brushed it. Bad luck, but no biggy.

After +- 2 hours and many positions in bath to get it cover everywhere in a nice coat of zinc, wooled it and got myself a nice bling bling yoke!

Part of it will be painted, the rest dipped after that in trans oil.

and so ended this rainy Saturday for me... Hope to spray something tomorrow, but looks like chances are very very slim I can..