Weekend!

Was expecting the alternator kit to arrive later next week, it was delivered yesterday.

As I have many boxes full of alternator parts, lets start the weekend with this baby to clear some room.

All its out- & inner parts being restored & painted, it should not take ages...

What a nice surprise! Unlike the kit picture (see prev posts) where only the regulator/diode and both bearings were offered,

The kit they sent me contains more than expected: new plastic insulators and the brushes assembly.

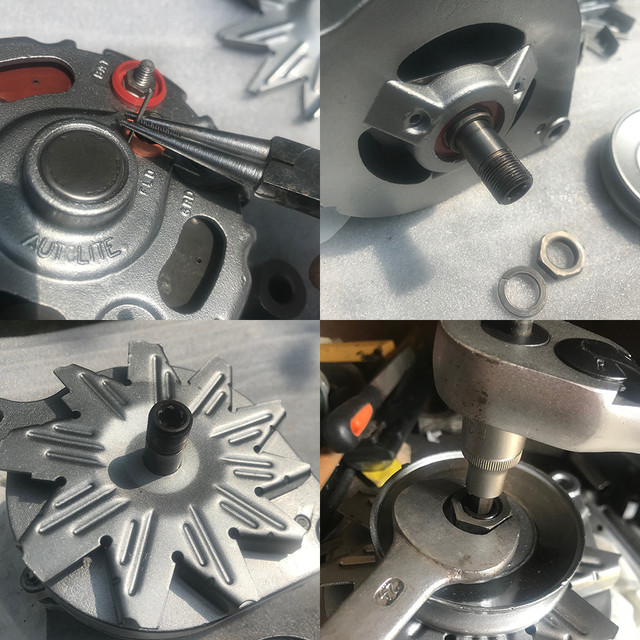

Now that all is clean and as new, its easy to put it back together. However, CJP doesn't know that I forget all within a few days, and its been several weeks since i've started on it and I was glad I took one or two pictures...

Here's a detailed recap of the reassembly.

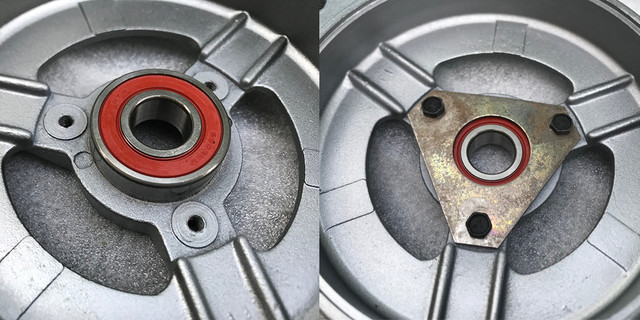

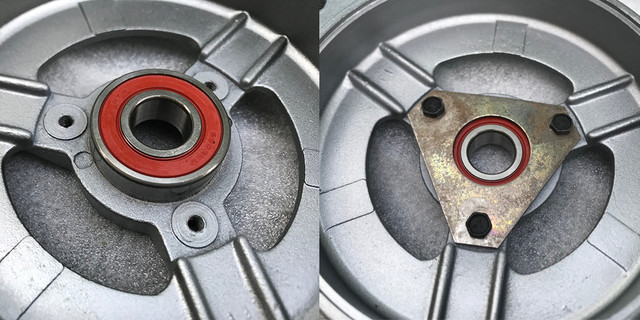

The old bearing that was looking fine was already removed so pushed the new one in place and secured it with the plate.

The bearing on the back body wasn't planning go anywhere and would have probably done the job for another 45 years.

So pressed it out with a 18mm socket that matches the diameter. Compared both and there were no differences except the shape of bottom. The new one, flat bottom, seams to be stainless steel.

As an alternator revs in the 10k RPMs, these have to be of good quality, that's probably why the old ones are still in great shape.

Installing the new one is the same, except done from the inside and due to reduced space, had to pick another socket to have a good flat start, as all was cleaned and greased, not much force was necessary, but it has to go to the bottom, aligned with the body.

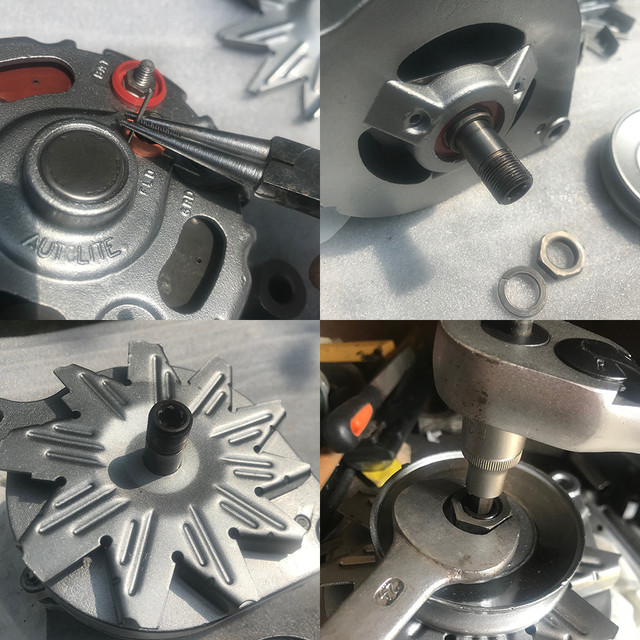

The brushes set is delivered pre-assembled and locked, awesome! Not need for the tape trick as with the wiper motor!

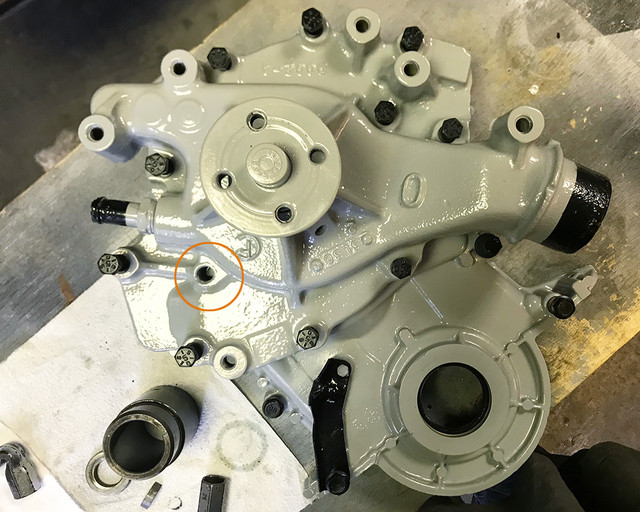

The little tube retaining the brushes under load, will go thru the hole that I've freed again before painting the casing and its where I was happy to have made pictures: The kit comes with zero doc, like if everybody knows the internals of an alternator on the top of his head and some b&w copy of some exploded view is considered a luxury. With their round shape the connectors of the brushes, you can easy forget the brush contacts do not go both to the 2 screws, but one needs go underneath and have a small insulator plate in between (not part of the kit). The original brush connector is square-ish, not round.

Bellow on the pict the left screw has no connection, the right one does, the upper one, the brush underneath connects to the port behind the casing (next pict)

The kits comes with new insulators, tho not all. The ones on the diode are not provided, and the orange one is white. While the old black one was cooked, the orange one was dirty but fine. So cleaned it and used it again instead of the white one. Also a detail, its important to not tighten the studs/nuts fully, first ensure the insulators are well center. You don't want power or false grounds on the casing!

One last cleaning of the diode assembly on the stator, as I can now "sandwich" back everything, the studs can fall, so taped them.

To put back the ballast/ diode, they is no possible error, the holes diameters prevents you to inverse the contacts, however, another missing item of the kit is the black insulator to the casing. Don't forget add one or like me, reuse the old one that should be ok.

After the diode assembly/stator is set back into the rear body, removed the tape and ensure all the insulators were centered.

As the brushes are not in the way, you can let the rotor take its place, not before adding a tad of extra grease on the shaft at the bearing and cleaned it with a very light layer of white grease just to prevent future corrosion.

Don't forget to add one of the spacers (ring) on the shaft. There is one on each side of the bearing! That's also something easy to forget!

Then its time to degree the alternator. Meaning, thx to my picts, I can set the front back onto it, being sure it will meet the original brackets for my engine.

Once secured, the casing and most important part of the alternator unit is done.

Its time to test if all rotates freely with no resistance and eventually reopen it if it doesn't.

Smooth as butter! I can continue my sandwich by adding the second spacer, then the fan. The pulley much more easy than getting it loose, this is now just an alen socket and to unscrew to screw it till you can't anymore. I didn't have doc on the torque required, tho pretty sure it's not going to get loose anytime soon!

Weeks after I first open it, the alternator puzzle is finally complete! YEEEEA!

At $20 the kit, more complete than expected, even if you do not paint or restore it (tho I hope you see it makes a massive diff), It's really worth it.

You are also way cheaper than buying a new alternator. Know that with a replica/restored version of this exact one, you will see costs rising between 200 and 400. (ex taxes and shipment).

The before and after pict!

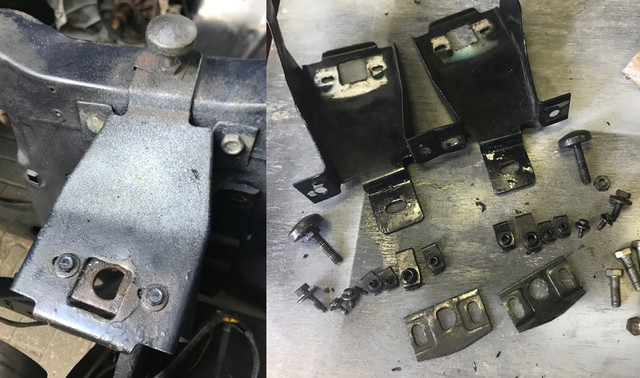

With all the brackets, bolts and nuts restored as well, I finally can say: Alternator: done!

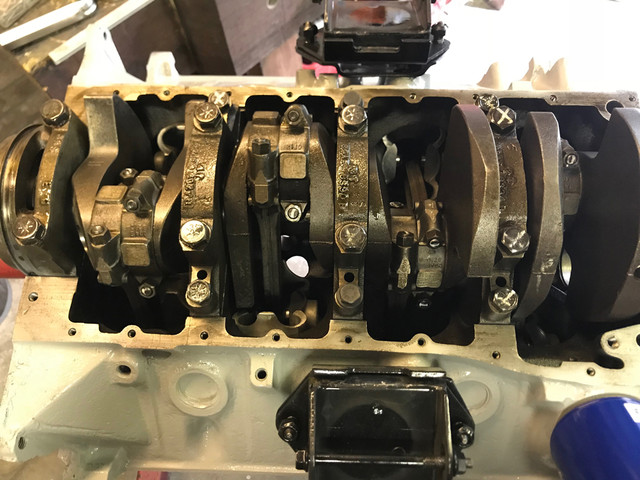

Rest of the day was for the 73 and probably a big chunk of tomorrow...

to be continued...