- Joined

- Mar 30, 2017

- Messages

- 2,418

- Reaction score

- 930

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

Weekend!!

And what normal people do on weekend???

I really don't know!

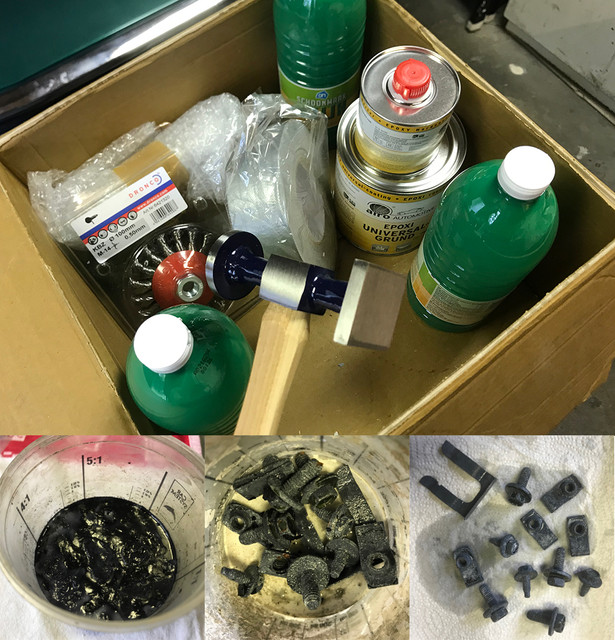

On my part I went check my week's brew!

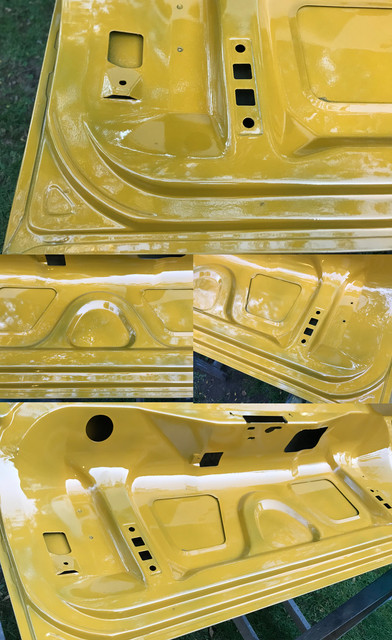

As I got lots of empty holes supposed to hold something, did a selection from my rusty spares last week on block, accessories etc...

Let them cook and as the nasty layer above suggest: they were ready!

Here some details of the rusty bolts out of bath, cleaned and prep. Finally got most holes used.

Some come from my 73 and some from god knows where. But these are all original Mustang bolts that I've kept over the years.

It's been said a few times: do not throw anything away, even if that looks bad!

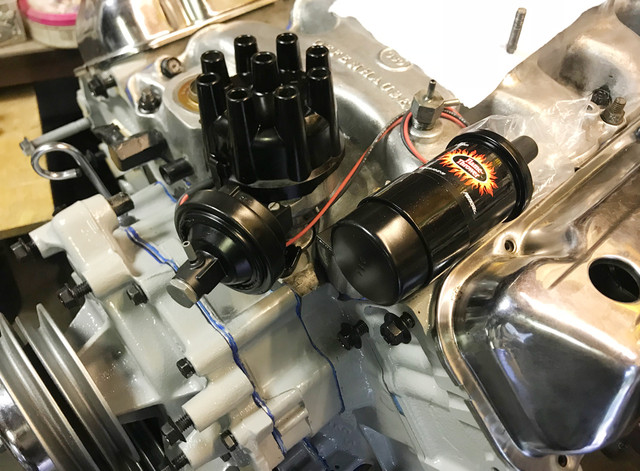

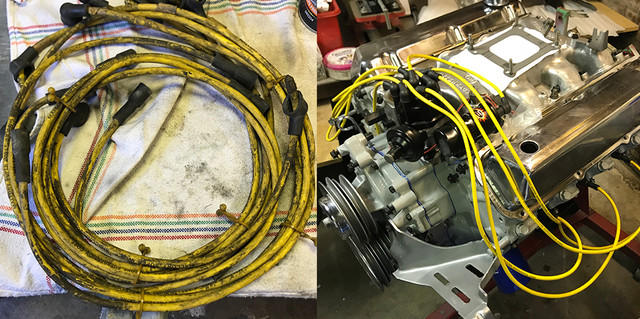

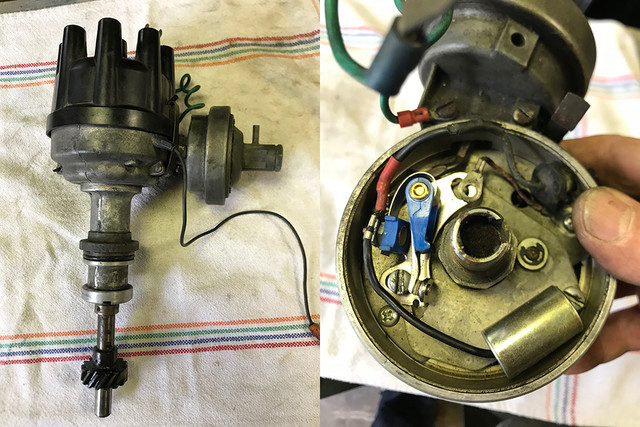

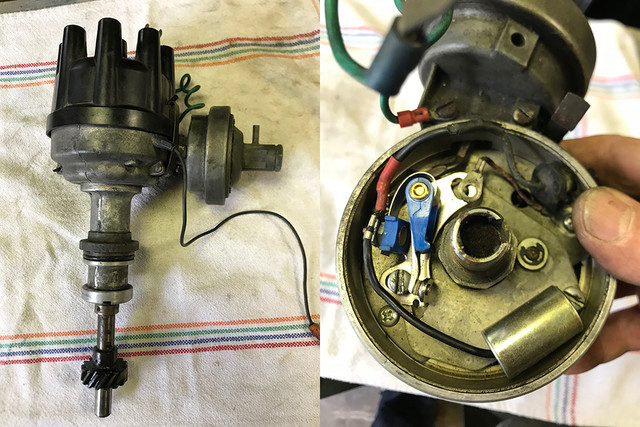

And then moved on to the next candidate in line: the distributor.

Thanks to Steve, aka @secluff. He searched (and of course he found) that the serial that I've provided him, was a match for the expected original distributor for the car. A 71 dual vac Autolite. I'm actually after making it a single for my EFI needs but for now, the goal is to see/inspect if this baby is worth keeping/restorating or if i should look at a replacement. Ranging from 80-250 for an average mechanical single vac diaphragm in the states, I would then be at my door for at least the double. The rotor and cap, while "ok", will be replaced if I keep it. So its worth looking at this survivor that was kept with the car parts while replaced on the car by some early 90's "electronic" dist that I do not trust for a second with a weird MSD box that is having modified electrics...

The only way to know is to open and inspect it, from gear to bearing, plates, weights etc..

As I have a new Pertronix waiting for a dist. The points, wires, condensator were removed and will not come back.

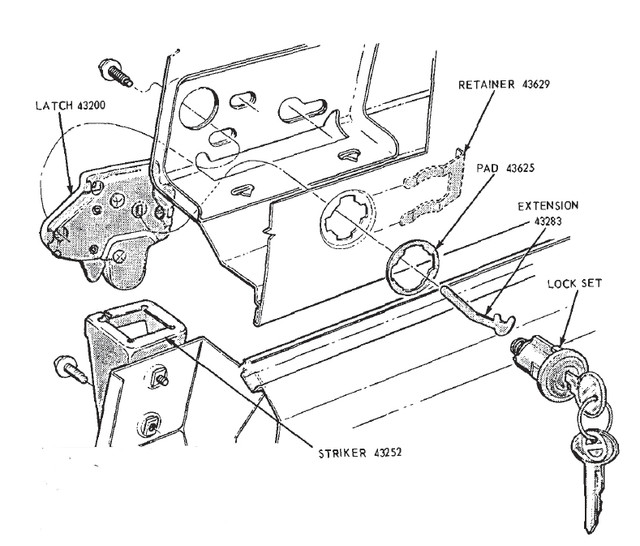

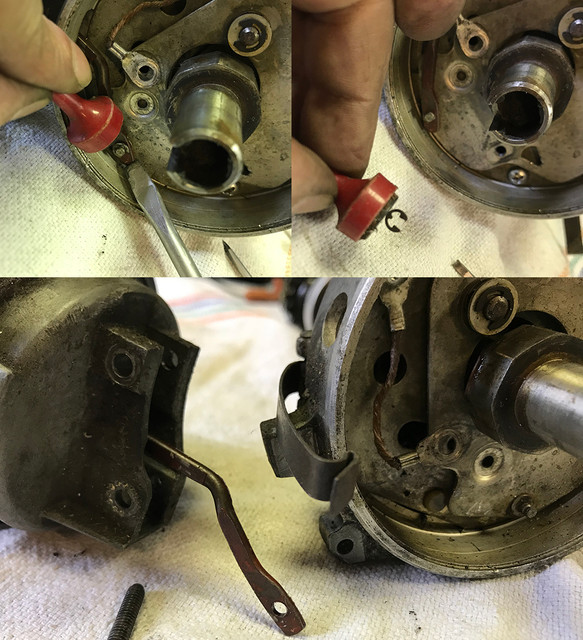

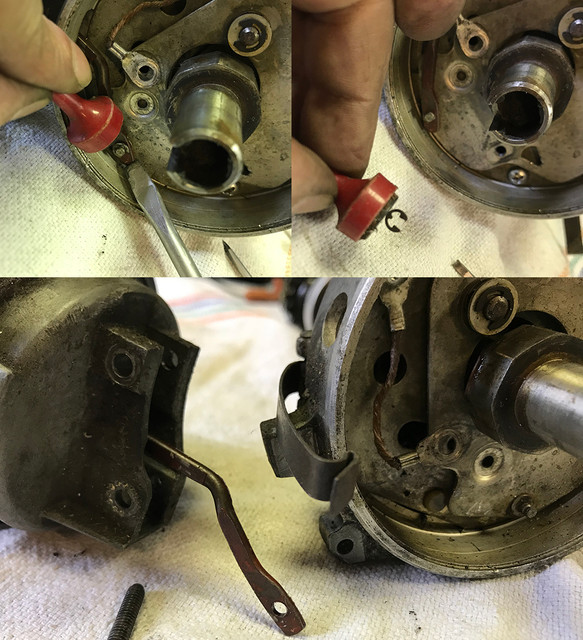

Once out it was time to disconnect the dual vacuum advance by loosing the tiny ear washers. I've used a magnet as they are very small and I was really not planning to go search for them somewhere on the floor.

Same treatment for the plate bellow, this plate has 3 pressure points so it can move/rotate with practically no friction.

So far, no play, no damage or excessive corrosion. Lots of dirt.

As all was looking good, quickly degreased and dipped the cap locks while busy on the first problem.

Someone at some point installed soft metal screws and did not bother oil them... decades later, no way to get them loose.

The heads totally gone no matter how good the screwdriver fits. I went to plan B and Mr Dremel entered the game.

4 tiny discs later, I won! Plate out I could inspect the weights. All ok. So I could consider remove the shaft.

To remove the shaft, you need to gently hammer out the retainers/pins. They go straight from one side to this other.

Too tiny to be pushed out for my tools, found out that an unused rivet does the trick perfectly. Slightly smaller than the pins themselves and strong enough to take the punches. The gear, very dirty but looking fine, needed be helped to get started. Once it moved a bit, finished the job with a lightweight 2 arms puller. Not much force required, but you would not be able to pull it with bare hands. Unlike the examples of autolite shafts I saw before, this one isn't having the same diameter and its slightly larger where the gear is...

Now that the entire dist was in parts, it was cleaning time....

Lots of cleaning, degreasing, polishing, sanding, cleaning, polishing further.

Thats how the ins and out started to look like: bling bling!

My full engine gasket set having a new o-ring for it. I've installed it and started to assemble the shaft back.

All in assembly lub and brushed with fine oil before being put back together, I got the shaft almost back in.

The ring and the top pin went back first and tried set back the gear, but forgot check alignment first.

Because they drillthe hole a tiny bit off center, there is a 50% chance you need to rotate the gear.

I've lost

So re-puller, turn 180 deg, re-press in, almost but no quite aligned yet..

Too dark to see the tiny bits of metal and starving, I called it a day...

I'll finish this tomorow...

And what normal people do on weekend???

I really don't know!

On my part I went check my week's brew!

As I got lots of empty holes supposed to hold something, did a selection from my rusty spares last week on block, accessories etc...

Let them cook and as the nasty layer above suggest: they were ready!

Here some details of the rusty bolts out of bath, cleaned and prep. Finally got most holes used.

Some come from my 73 and some from god knows where. But these are all original Mustang bolts that I've kept over the years.

It's been said a few times: do not throw anything away, even if that looks bad!

And then moved on to the next candidate in line: the distributor.

Thanks to Steve, aka @secluff. He searched (and of course he found) that the serial that I've provided him, was a match for the expected original distributor for the car. A 71 dual vac Autolite. I'm actually after making it a single for my EFI needs but for now, the goal is to see/inspect if this baby is worth keeping/restorating or if i should look at a replacement. Ranging from 80-250 for an average mechanical single vac diaphragm in the states, I would then be at my door for at least the double. The rotor and cap, while "ok", will be replaced if I keep it. So its worth looking at this survivor that was kept with the car parts while replaced on the car by some early 90's "electronic" dist that I do not trust for a second with a weird MSD box that is having modified electrics...

The only way to know is to open and inspect it, from gear to bearing, plates, weights etc..

As I have a new Pertronix waiting for a dist. The points, wires, condensator were removed and will not come back.

Once out it was time to disconnect the dual vacuum advance by loosing the tiny ear washers. I've used a magnet as they are very small and I was really not planning to go search for them somewhere on the floor.

Same treatment for the plate bellow, this plate has 3 pressure points so it can move/rotate with practically no friction.

So far, no play, no damage or excessive corrosion. Lots of dirt.

As all was looking good, quickly degreased and dipped the cap locks while busy on the first problem.

Someone at some point installed soft metal screws and did not bother oil them... decades later, no way to get them loose.

The heads totally gone no matter how good the screwdriver fits. I went to plan B and Mr Dremel entered the game.

4 tiny discs later, I won! Plate out I could inspect the weights. All ok. So I could consider remove the shaft.

To remove the shaft, you need to gently hammer out the retainers/pins. They go straight from one side to this other.

Too tiny to be pushed out for my tools, found out that an unused rivet does the trick perfectly. Slightly smaller than the pins themselves and strong enough to take the punches. The gear, very dirty but looking fine, needed be helped to get started. Once it moved a bit, finished the job with a lightweight 2 arms puller. Not much force required, but you would not be able to pull it with bare hands. Unlike the examples of autolite shafts I saw before, this one isn't having the same diameter and its slightly larger where the gear is...

Now that the entire dist was in parts, it was cleaning time....

Lots of cleaning, degreasing, polishing, sanding, cleaning, polishing further.

Thats how the ins and out started to look like: bling bling!

My full engine gasket set having a new o-ring for it. I've installed it and started to assemble the shaft back.

All in assembly lub and brushed with fine oil before being put back together, I got the shaft almost back in.

The ring and the top pin went back first and tried set back the gear, but forgot check alignment first.

Because they drillthe hole a tiny bit off center, there is a 50% chance you need to rotate the gear.

I've lost

So re-puller, turn 180 deg, re-press in, almost but no quite aligned yet..

Too dark to see the tiny bits of metal and starving, I called it a day...

I'll finish this tomorow...

Last edited by a moderator: