Who is this “Winnie”? ;-)

Great to hear that my nut...errrr Hardware is working fine on your engine!! :whistling:

Hahaha, sorry guys, I swear I did not drink a drup, @W... @Vinnie is my witness!. I should not write anything when I'm tired!

Fabrice:

Just wanted to drop you a note that I love your weekend updates and how lovingly you document all of your fine work. Please continue; I will miss these updates tremendously once all is done and the car is completed.

Thanks again.

Mid.

Thx Randy, glad you enjoy this serie B like I do enjoy making it

Its a bit like in these bad series, where nothing much happend, yet you look at them and the show fills one hour!

Hope you can wait till I enter the electrics chapter!

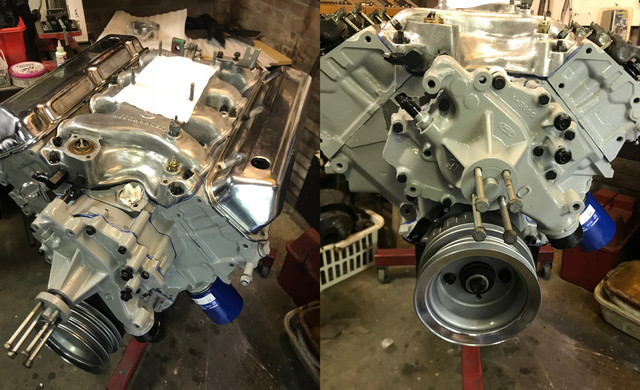

The day started with finishing the boring clean ups and installs of the rockers, pushrods... of the other side

Here a nice close up at these US made quality parts in fine oil.

They weight a ton and have stupid corners in their shape where deposits are hard to get out..

but they surely show off that in 71, the stuffs Ford was making was no mickey mouse stuff like you see today.

Let's add a tad of drama to this sunday episode...

All was installed and next was the intake, so I went check all again, went thru each one of the pushrods and one of lifter wasn't "pumping" as the others.

Just a small pressure was enough to bring it to its max spring compression. It was more a solid than an hydraulic lifter.

Because I've pumped them with oil yesterday using my thumb, the pressure wasn't enough to feel the difference.

As I throw away only the used parts for my wife's car. I had the previous set of lifter's, Crower or Lunati from the previous config somewhere..

Way less ferm than the new one, I decided to take one and open it to see how these things are put together. They all have these clips/retainers

and it took just 1 broken nail to open one. (up on the pict).

Because it was easy and because I could not stand the idea to close the engine with a weird lifter, I've bravely ignored the fact that if I would F... up that one, I'd need to wait 3 weeks to get a new one.

I open the new one and aside the clip, they are totally different inside. The Summit one has some inner cylinder, and wasn't springy at all.

While trying to get that cylinder out upside down with some circular motion, I felt something and it was springy as it should have been.

The spring underneath the cylinder engaged properly on the pin underneath when pressure was released. The little guy was simply not correctly put together at the plant, it was somehow sandwiched. Placed back the small valve, the oil "nozzle" and set back the clip. Dip it again in oil..

Back on the engine. Fingers crossed: all fine and just like the others! yeah!

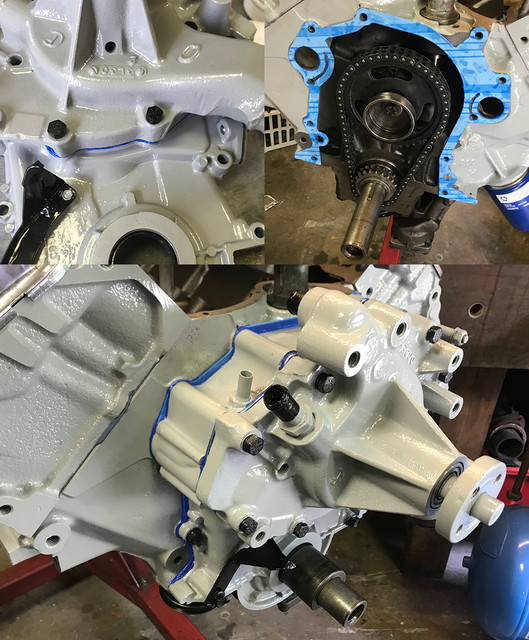

After a blanc test, I was happy to see that the rubber and metal gasket were this time cut ok, and even the lips to lock them together were fine.

One last inspection of the lifter bay. All fine and super clean.

Blue Loctite smel in garage...

A few minutes later, the restored hardware under 2.5 to 4.1 kgf was in place. Because all was well cut this time, very little cleanup of the paste was necessary.

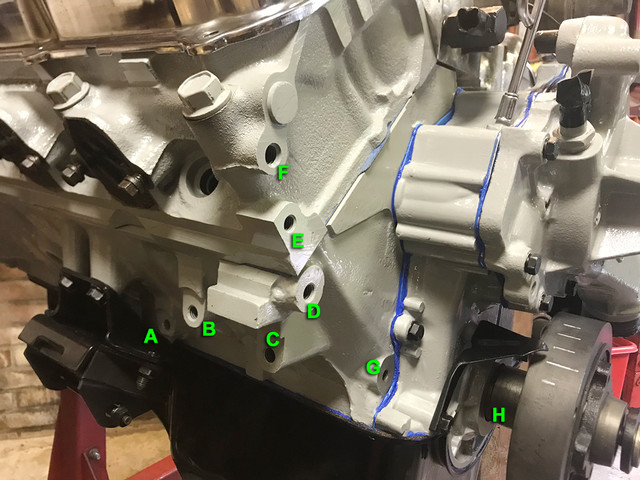

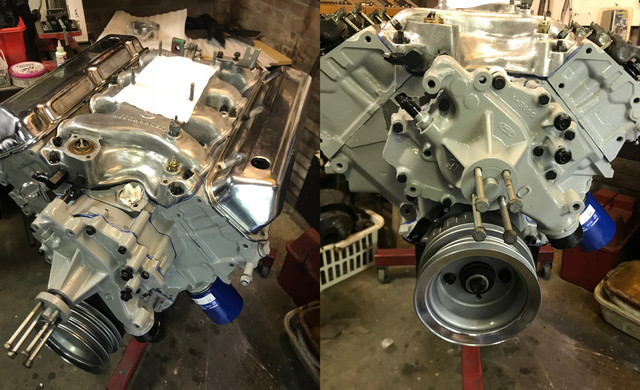

Started place back some of the accessories. And I now can see i'm almost there.

Just a few unused holes left, but pretty sure the missing bolts are with the restored brackets.

The water neck, will be replaced with a new one. The aftermarket in aluminium is badly corroded and the original weird electric 3 ways vacuum thingy on top of it has no reason to be for an EFI and as I need a place for a second temp sensor somewhere...

All with all looks like i'm almost done with the engine. I will adjust the valves just a bit more but will not set the prings under pressure. I'll do this right before putting back the engine into the car.

To be continued...