- Joined

- Mar 30, 2017

- Messages

- 2,418

- Reaction score

- 930

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

@Randy

[Might be available as 4 pin trailer connectors, but I can cobble up a mating pair for you. ...]

Excellent, I'll PM you once I'll know more on the extend of the damage on the other side of the firewall.

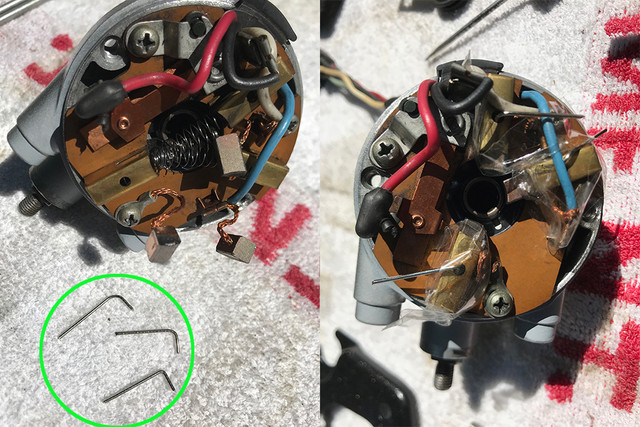

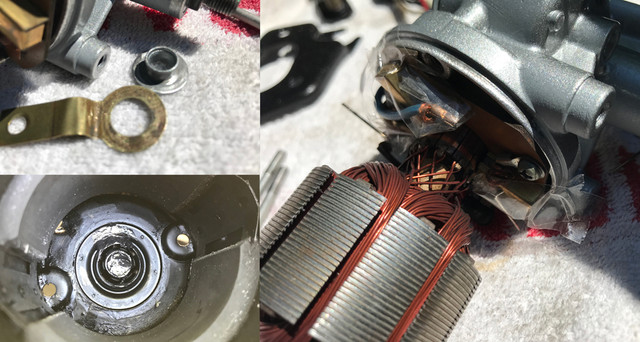

[if you find a used wiper motor, it should come with a good connector on it.]

I'm gonna search for car/parts of similar years and see if I can locate some over here.

@David

[i did not read every line of the post]

You don't like my english???

[i do not have the stud you need Sorry.]

No problem, Steve managed to locate the missing nut and 3 others specific lock nuts for the engine mount to block. On my side, found back important & missing hardware that were stored with non engine related parts and others were still on the block. As It was protected under a thick air tight layers of plastic, I did not know they were there. Cross my fingers, but looks like I may have all the necessary for the engine now.

Still after that power window bezel tho.

@Steve

[Dark Ivy Green Metallic]

That's correct, the car has been repainted once in black with a mix of gold stripes, and lower body in grey. After removing parts, I was able to see the green.

From what I saw, the black paint job was not done to the bone, so I expect to find back the original layer of green at many places.

Build sheet : The original carpet is still inside, so may be i'll find it at some point. I also got a pile of papers of all kinds with the car that I still need to sort and go thru, may be it's there. So far, the car seams to have nice options for a 71. Its a deluxe interior, power disc brakes, rear defrost, radio+speakers, has power windows front and quarters, has the convenience group, map light is there. got the 3 gauges. Console is there but missing the ashtray and the clock. Its having the fold down rear seat, and only missing one of the trunk door handles. It has the thin trim mid body and it looks like the car was AC too, as the console as the airco panel and the glove box is not deep. Tho, i'm not 100% sure yet if these were installed out of necessity or if it was indeed an AC car.

I'll go thru the interior once I have freed enough space to store it while busy on the body. From a quick inspection, floor looks solid on exception of driver front seat cup where water has entered the car and never left.

[Might be available as 4 pin trailer connectors, but I can cobble up a mating pair for you. ...]

Excellent, I'll PM you once I'll know more on the extend of the damage on the other side of the firewall.

[if you find a used wiper motor, it should come with a good connector on it.]

I'm gonna search for car/parts of similar years and see if I can locate some over here.

@David

[i did not read every line of the post]

You don't like my english???

[i do not have the stud you need Sorry.]

No problem, Steve managed to locate the missing nut and 3 others specific lock nuts for the engine mount to block. On my side, found back important & missing hardware that were stored with non engine related parts and others were still on the block. As It was protected under a thick air tight layers of plastic, I did not know they were there. Cross my fingers, but looks like I may have all the necessary for the engine now.

Still after that power window bezel tho.

@Steve

[Dark Ivy Green Metallic]

That's correct, the car has been repainted once in black with a mix of gold stripes, and lower body in grey. After removing parts, I was able to see the green.

From what I saw, the black paint job was not done to the bone, so I expect to find back the original layer of green at many places.

Build sheet : The original carpet is still inside, so may be i'll find it at some point. I also got a pile of papers of all kinds with the car that I still need to sort and go thru, may be it's there. So far, the car seams to have nice options for a 71. Its a deluxe interior, power disc brakes, rear defrost, radio+speakers, has power windows front and quarters, has the convenience group, map light is there. got the 3 gauges. Console is there but missing the ashtray and the clock. Its having the fold down rear seat, and only missing one of the trunk door handles. It has the thin trim mid body and it looks like the car was AC too, as the console as the airco panel and the glove box is not deep. Tho, i'm not 100% sure yet if these were installed out of necessity or if it was indeed an AC car.

I'll go thru the interior once I have freed enough space to store it while busy on the body. From a quick inspection, floor looks solid on exception of driver front seat cup where water has entered the car and never left.