Ok, well you asked for it!

A few years ago now I lowered the UCAs on my Mach1. Previously I had a '70 coupe on which I wore the outside of the tires down to the cords because of hard cornering. I became aware of the Arning drop but I did not know the 71-73 geometry had changed – it looks the same to me! I was inspired by availability of a kit for 71-73s in the NPD catalogue that stated the arm was lowered by 1.75". Living in the UK makes all parts from the USA expensive so I went for a DIY approach. I needed to replace the UCA shaft & bearings anyway. While it was apart I welded some reinforcement on the arm. I fabbed wedge plates for the ball joints from aluminium. This was the most tedious part of the job as I don't have a mill.

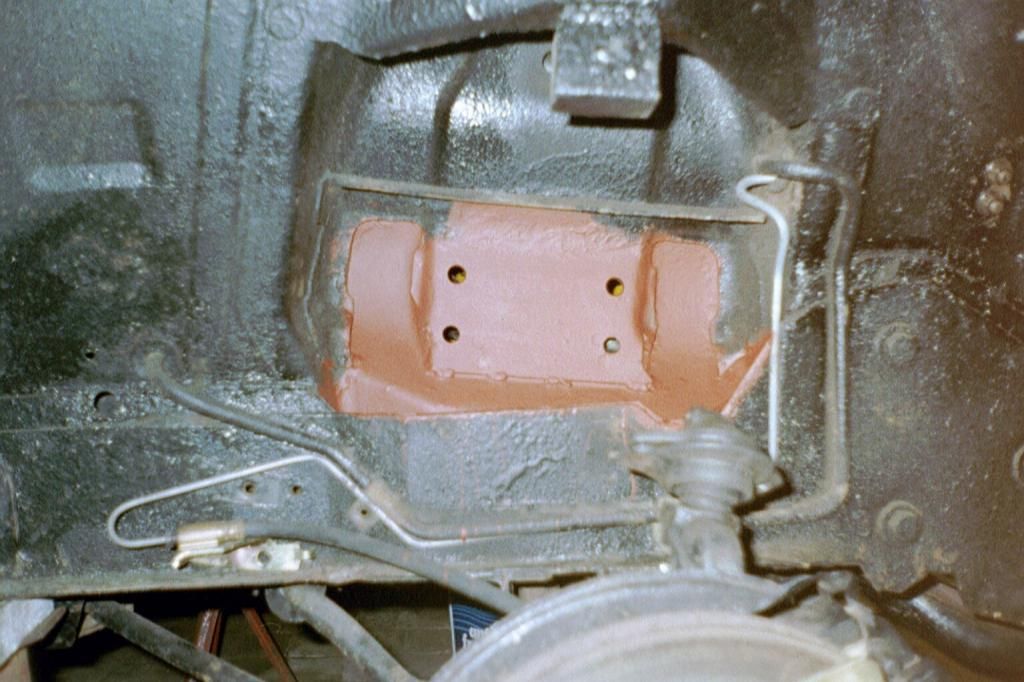

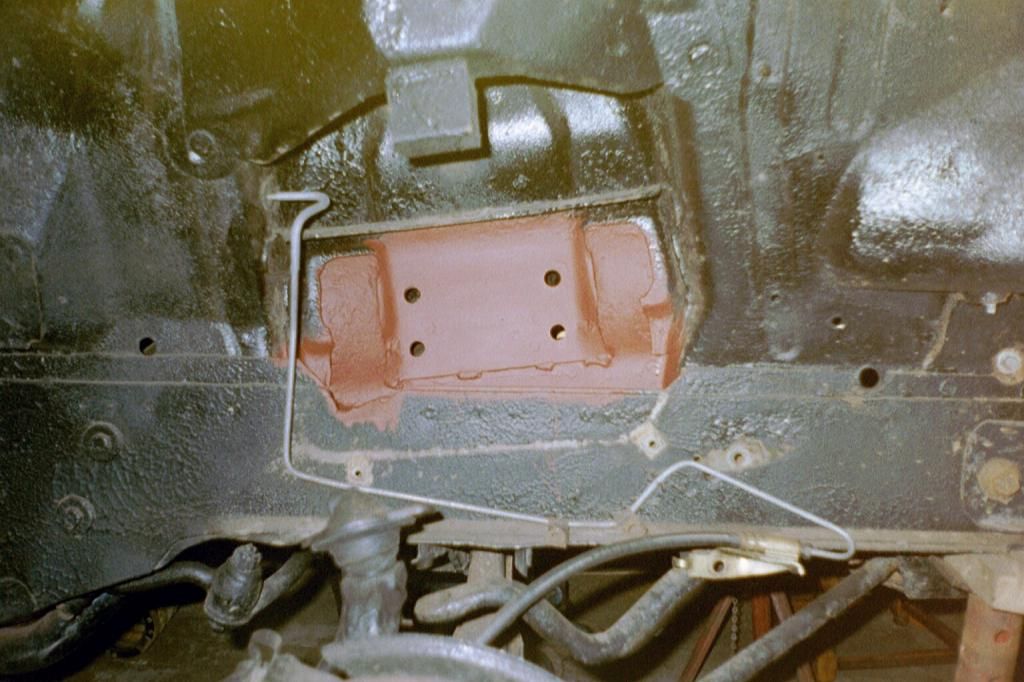

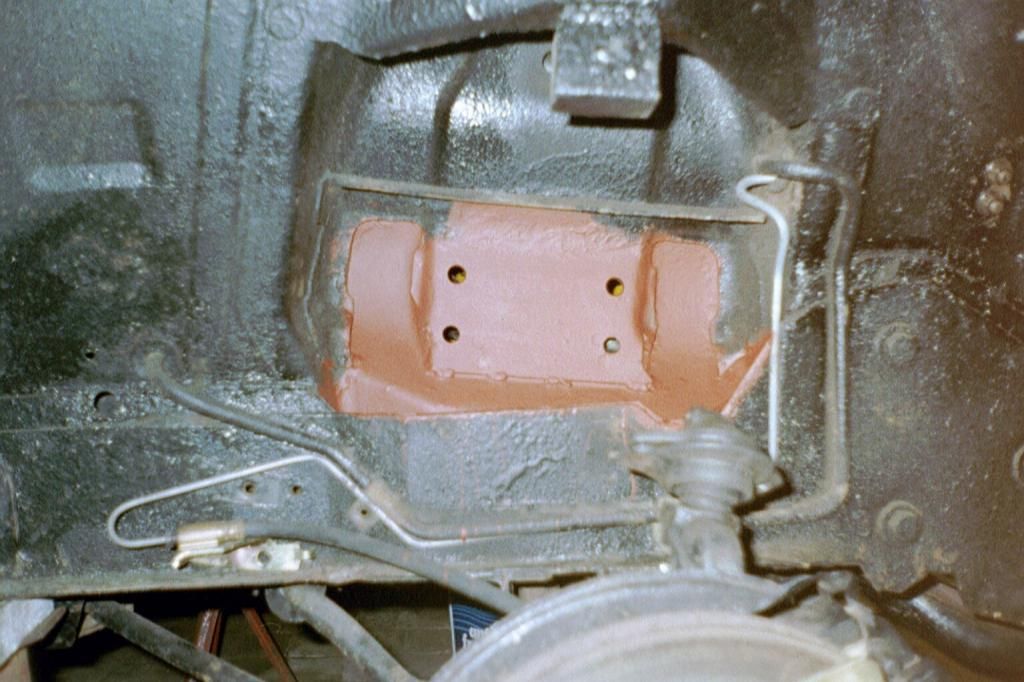

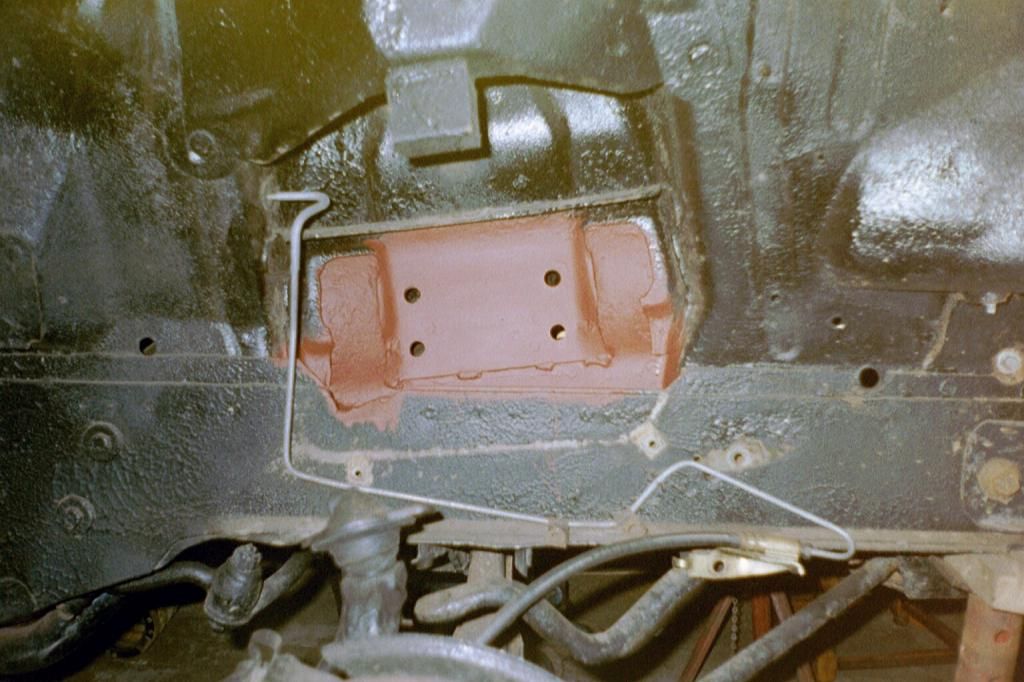

I then made an aluminium template that I could secure to the original mounting holes with studs sticking out to test the new arm location before drilling. It seemed to be ok. I had to do delicate surgery with a cutting disk to get the lower reinforcement out of the way. I welded it's lower edge down and added an additional reinforcement plate of 16 gauge which is also bolted to the original holes (not in these photos).

Drilling the new holes was an issue as the 9/16” hole went thru the edge of a layer of sheetmetal in the engine bay. I think I drilled thru 3 ½ layers of metal. The drill hung up on a weld on one hole, slamming my hand into the shock tower reinforcement and bending the drill shaft a bit. I had to fabricate stepped washers for these locations. I installed the arms with dampers (Konis off the 70 with top brackets to match) but no springs so I could test the full range of movement. On the left side of the car there is already a notch in the frame giving clearance for the dropped arm at full droop.

I had to cut and weld up a notch on the other side.

Even so I had to add 1” spacers under the top damper bolts to prevent the arms hitting the rails. Later I bought some of the taller early upper brackets (65?) and they worked fine. The Konis were sticky with age so I put on some KYBs later and was able to go back to the 70 upper bracket as the KYBs are shorter. I also had to weld a platform on the end of the UCAs to make a square contact with the bump stop.

The other point to be aware of is that the further the arm is lowered, the less suspension travel you have because the outer end of the arm gets closer to the bump stop (it has pivoted about the spring seat). The amount I lowered it is the absolute max with stock parts as part of the spring seat touches the top of the UCA at full bump and it cannot be relieved without major mods to the UCA.

Full droop:

Full bump:

Another issue that cropped up when I took it to get aligned is that the camber could only just be set to zero, probably because the lower mounting position is further out than the original and also because of the re-inforcement plate I fitted.