Hello David, Many thanks.

I have now found the information I needed and thought I would share this as the Youtube Videos do not have this information.

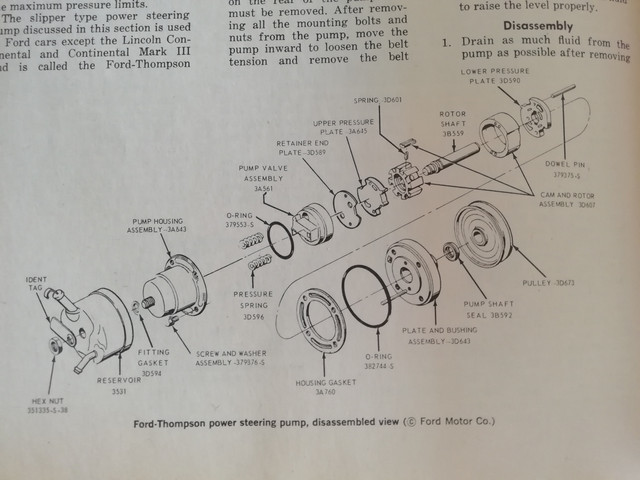

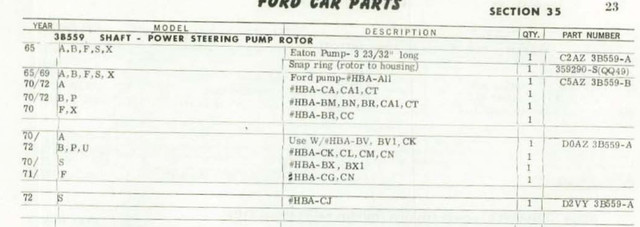

Ford, Thompson Power Steering Pump.

The 4 bolts holding the inner pump body to the cast pump body should be torqued to

28-32 ft-lbs until the housing flange contacts the gasket.

Check the rotor shaft for binding, Place a 3/8-16 Hex head screw into the end of the pump spindle and put a torque wrench on it, If the torque is more than

15 in-lbs, loosen off the retaining bolts slightly and rotate the rotor shaft, re-tighten bolts and check again for alignment /binding.

The rear nut holding the outer body to the pump should be torqued to

43-45 ft-lbs

Info from Chilton 1971 ::thumb::

Pump rebuild O ring service tool Ford Part Number T69P-3B586-A

I could not find this tool so I made my own.....

The purpose of this tool is to stop the smaller rubber O ring on the upper end of the pump catching in the oil slot on the pump body. As you tighten down the bolts there is the possibility of the O ring getting damaged.

1/ First thing I did was degrease the pump body, next I got some masking tape and carefully masked the walls of the oil slot, then put a larger piece of masking tape on the outside of the pump body.

2/ Mixed up some Household 2 part filler and squeezed it through the Oil slot and built it up into a block on the outside of the pump body.

3/ When the filler was semi dry, I then trimmed off the excess filler so that it was flush to inner face of the pump body, followed by a final sand (when the filler had fully dried) with some wet/dry paper fine grit so as not to damage the pump body.

4/ I then pushed the block of filler out of the slot and removed the masking tape from the oil slot and pump body,

This is what you should end up with ::thumb::

5/ Using a large adjustable pipe clamp I then fitted it over the new service tool and tightened clamp to hold it in place.