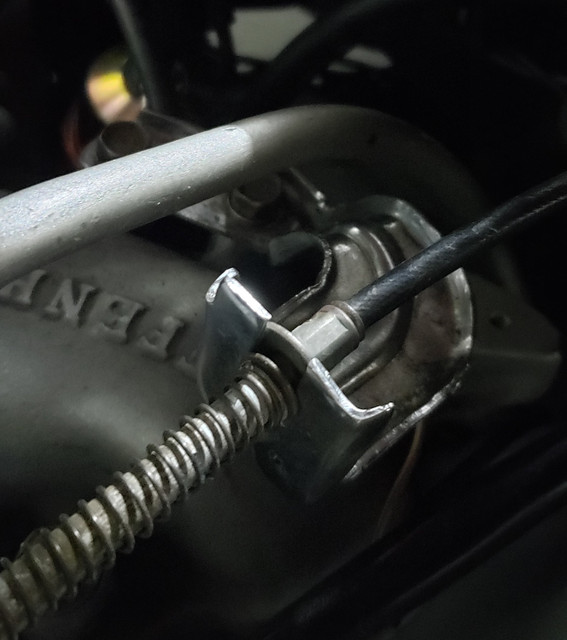

Even with using the larger hole my cable is STILL 3/4" ahead of that hole too. Definitely new bracket time.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Throttle cable

- Thread starter Omie01

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Aug 14, 2014

- Messages

- 4,542

- Reaction score

- 1,588

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

If too long you can cheat by looping the cable aroung a screw. Then you tighten it with a nut & washer. In this manner you can shorten it depending on the diameter of the screw and how many turns you go around. I have done it several times.

Sent from my SAMSUNG-SM-G930A using Tapatalk

Sent from my SAMSUNG-SM-G930A using Tapatalk

machattack

Well-known member

- Joined

- Apr 27, 2019

- Messages

- 724

- Reaction score

- 264

- Location

- Idaho

- My Car

- 1971 mustang mach 1 351c 4v auto fmx

1968 mustang gt 302 4v 4 speed

Well, there is a ton of (mis)information out there. I've also read that the bracket we have will work for both. However, clearly not in my case at least.

Last edited by a moderator:

- Joined

- Dec 28, 2014

- Messages

- 2,945

- Reaction score

- 625

- Location

- Washington Twp. Mi

- My Car

- 1972 Mach 1 Q Code

Here’s my set up. I have a 4v car and this is the original bracket. What I had to do was put some tall spacers under the bracket where it mounts to the intake. I have a Blue Thunder and is a bit taller than stock. Everything fit great and since this pic I have removed the bottom extra return spring. Anyway I can get better pics of how I bolted it to the intake tomorrow if you want.

$18.77

$24.95

Ford Mustang Pony Racing Stripe 5.0 Muscle Shelby Long Sleeve T-Shirt Front Back Print-Black-Large

Giftware Shop Usa

$35.00

$49.95

Ford Mustang (2005-2014) Haynes Repair Manual (USA) (Paperback)

Haynes Repair Manuals

$37.95

$49.99

Lucky Ride MUSTANG PONY HOODIE GRILL WITH FORD CAR HOODED SWEATSHIRT, Black, L

Giftware Shop Usa

$13.75

$16.39

Ford Mustang: Trivia & Fun Facts Every Fan Should Know About The Great American Icon!

Amazon.com

$99.99

Polished Rocker Panel Sill Plate Molding Kit with Clips Compatible with 1964-1966 Ford Mustang - Authentic Restoration for Classic Car Enthusiasts

Classic 2 Current Fabrication

$11.99

$19.98

100 Cars That Changed the World: The Designs, Engines, and Technologies That Drive Our Imaginations

Amazon.com

$31.52

$60.00

Shelby American 60 Years of High Performance: The Stories Behind the Cobra, Daytona, Mustang GT350 and GT500, Ford GT40 and More

WhitePaper Books

$50.27

Scott Drake Ignition/Door/Trunk Lock Set, Compatible with 1967-1969 Ford Mustang, Model C7AZ-6222050-MK

Holley Performance Product

$22.97

$32.58

Sunex 212zum 1/2-Inch Drive 12-Mm 12-Point Universal Impact Socket

Elite Tool Center

$9.00

2016 Hot Wheels Vintage American Muscle 1970 FORD MUSTANG MACH 1 die-cast 4/10

Cards and Bobbles

$64.98

JH DESIGN GROUP Men's Ford Mustang Collage Black Zip Up Hoodie Sweatshirt (Medium, CLG2-black)

Affordable Family Clothing

$28.52

$29.95

Ford Mustang, Mach 1, GT, Shelby, & Boss V-8 (64-73) Haynes Repair Manual

Haynes Repair Manuals

$50.12

$55.00

The Complete Book of Ford Mustang: Every Model Since 1964-1/2 (Complete Book Series)

Amazon.com

I used it. The tension is adjustable.Tommy, Did you utilize the spring in the front, or did you just discard that?I solved this problem by using an aftermarket throttle cable bracket that allows adjustment of the cable mounting point.

https://www.summitracing.com/parts/aed-6601bk

Appreciate the offer jpaz. I was definitely looking at moving the stock bracket up. But that still won't help the fact that it needs to still come 5/8 to 3/4" back toward the firewall. I'm going to order a new cable(why not) and the system that TommyK is using and move on.

- Joined

- Jan 1, 2012

- Messages

- 8,540

- Reaction score

- 1,411

- Location

- Eugene, OR

- My Car

- 1971 Mustang Sportroof M code

Information on the two different brackets

https://secure.cougarpartscatalog.com/d1zz-9728-e.html?attribs=82

https://secure.cougarpartscatalog.com/d1zz-9728-e.html?attribs=82

boilermaster

Well-known member

Ok Fellas,

Your posts just got the best of me, so I went to my parts car, 73 q code 4 sp. car and pulled the bracket, as it looked completely different from the current bracket that I am currently using.

First of all my current bracket (believed to be from a 302 2v) allows 100% opening from the loud pedal.

I then removed it and used a square and marked where the attachment holes were in relationship to the cable attachment.

Then I did the same to the Q bracket, same exact measurement, I would have sworn that the q bracket was longer and thus push the ball clip to a

more forward position, this did not happen.

With both brackets I am seeing the ball clip ahead of the ball stud by approx. 1/2'' (my Q bracket looks like the one Big Red Mach 1 posted a picture of)

My little test this morning leads me to two possibilities : the ball studs are too far rearward on the carb lever or not all intake manifolds are of the same orientation (their bracket location to carb pad location may be different).

Boilermaster

Your posts just got the best of me, so I went to my parts car, 73 q code 4 sp. car and pulled the bracket, as it looked completely different from the current bracket that I am currently using.

First of all my current bracket (believed to be from a 302 2v) allows 100% opening from the loud pedal.

I then removed it and used a square and marked where the attachment holes were in relationship to the cable attachment.

Then I did the same to the Q bracket, same exact measurement, I would have sworn that the q bracket was longer and thus push the ball clip to a

more forward position, this did not happen.

With both brackets I am seeing the ball clip ahead of the ball stud by approx. 1/2'' (my Q bracket looks like the one Big Red Mach 1 posted a picture of)

My little test this morning leads me to two possibilities : the ball studs are too far rearward on the carb lever or not all intake manifolds are of the same orientation (their bracket location to carb pad location may be different).

Boilermaster

boilermaster

Well-known member

The current bracket that I am using, (believed to be 2v or a mutt) looks nothing like either of the pics that Don C. just posted.

I think the issues lie in where the carb is being located on the throttle shaft or with the intake manifold attaching points.

Boilermaster

I think the issues lie in where the carb is being located on the throttle shaft or with the intake manifold attaching points.

Boilermaster

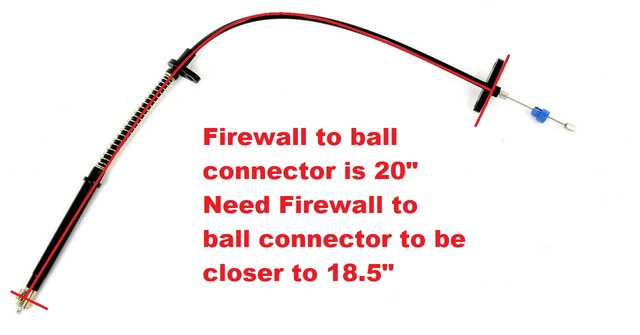

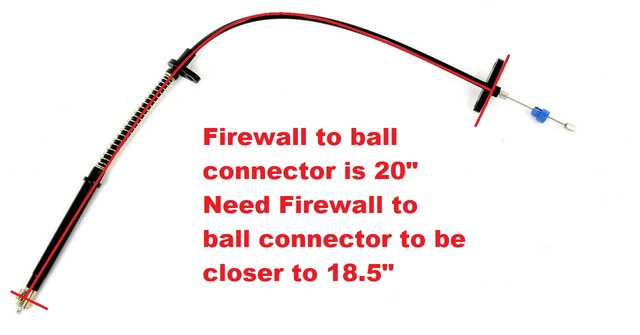

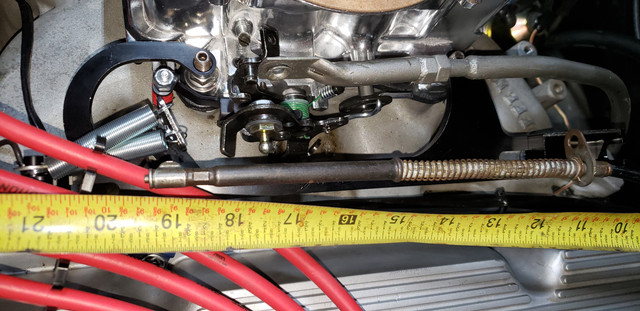

My cable is too long. I need about 18 to 18.5" from the firewall to the ball socket. My current cable is 20. I'm checking with Don at OMS to see if his cable might work. I'm hoping I have the wrong cable installed and that the standard cable is the cable I need. Even with the adjustable bracket, there's just nowhere to shove 2 extra inches of cable.

- Joined

- Sep 12, 2015

- Messages

- 8,060

- Reaction score

- 3,164

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

Last edited by a moderator:

If I had to guess, It's the orientation of the carb on this Offenhauser 360 intake. The Holley carb was the same way. That's why Eddie bent the linkage and drilled additional holes on the Holley. I'm not willing to do that on this Summit carb. In order to hook it up anywhere, I have to compress the spring so much that it actually puts so much pressure on the primary shaft that it actually increases idle. I thought the new adjustable bracket would work , and it will, but there's nowhere for the excess cable to go. Shorter cable is my only option.

Last edited by a moderator:

- Joined

- Sep 12, 2015

- Messages

- 8,060

- Reaction score

- 3,164

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

@ Big Red Mach1, Ah, now I see what you're dealing with, a funky intake!! Are you sure you can't find a way to take up 1/12" of extra cable between the bracket and firewall?

No idea if shorter cables are available other than make you own.

No idea if shorter cables are available other than make you own.

Honestly, it sounds silly, but not without bending it to the point that I feel it won't end up prematurely wearing the inside of the sleeve. I do believe I have possibly found my fix though. The throttle cable for Ford Torino may work. Waiting one one more detail from the seller. Length is perfect. Just want to make sure it has the same firewall mount.

- Joined

- Sep 12, 2015

- Messages

- 8,060

- Reaction score

- 3,164

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

Where there's a will, there's a way. hope that works for you.Honestly, it sounds silly, but not without bending it to the point that I feel it won't end up prematurely wearing the inside of the sleeve. I do believe I have possibly found my fix though. The throttle cable for Ford Torino may work. Waiting one one more detail from the seller. Length is perfect. Just want to make sure it has the same firewall mount.

On mine which is all stock apart from the carb, there is about 3/8" to 1/2' compression on the cable spring. There needs to be some compression to make sure the T/plates close, assuming that no extra springs are used. I have no issues reaching WOT.

Yup. That's about the amount of compression I'm looking for. Right now I'm super compressed (Over an inch) and cannot reach WOT.

- Joined

- Aug 14, 2014

- Messages

- 4,542

- Reaction score

- 1,588

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

On mine I had to install a bushing to move the cable support backwards plus used the trick I posted earlier where I winded the cable around a bolt/nut. Being able to fully open the butterflies at WOT is crucial for speed...... when I got my car from the previous owner the butterflies only opened about half. The good thing about is that it indicated that he was babying the engine.

- Joined

- Sep 12, 2015

- Messages

- 8,060

- Reaction score

- 3,164

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

That would be a concern for sure. Hope you find the solution. All good stuff to help others (including Omie1.)Yup. That's about the amount of compression I'm looking for. Right now I'm super compressed (Over an inch) and cannot reach WOT.

Similar threads

- Replies

- 40

- Views

- 3K

- Replies

- 10

- Views

- 740

- Replies

- 11

- Views

- 981

- Replies

- 15

- Views

- 1K

Parts For Sale

Original Ford 2V carb for 351C

- Replies

- 0

- Views

- 244