- Joined

- Mar 30, 2017

- Messages

- 2,418

- Reaction score

- 930

- Location

- The Netherlands

- My Car

- 73 Grande 351C

71 Mach 1 429CJ

Temp above 20c, sunny, Spring is here!!

The first brushes of the year are finally out!

Good kuz, I was using the autumn left overs

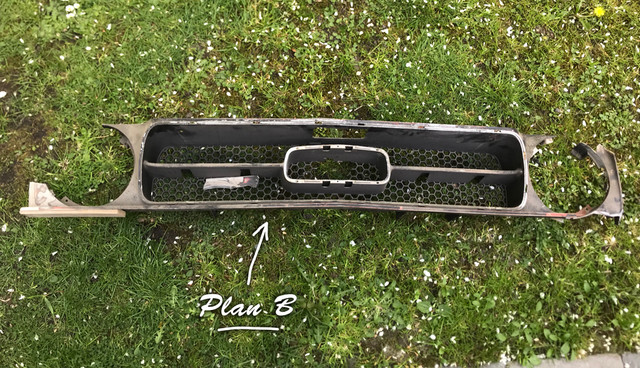

Before go search for hidden eggs, started by finishing the 2 headlight assembly parts.

Both were having lots of corrosion and passed the week in vinegar.

A wool massage in the sun, some cleanup and a few volts later, the first one was ready.

The last one, still having bits of rust in its deep pits, received few drups of elbow oil, and was done not long after that.

The second headlight assembly now plated, it was time for a group picture before next step.

After all this work to restore these parts to a rust free and protected condition.

It took less than a minute to ruin their shine with the first layer of epoxy!

Bye bye bling bling!

I wanted to have a thick layer applied today on the ones with the most scars, so I can sand them a bit tomorrow,

before they all receive a final coat.

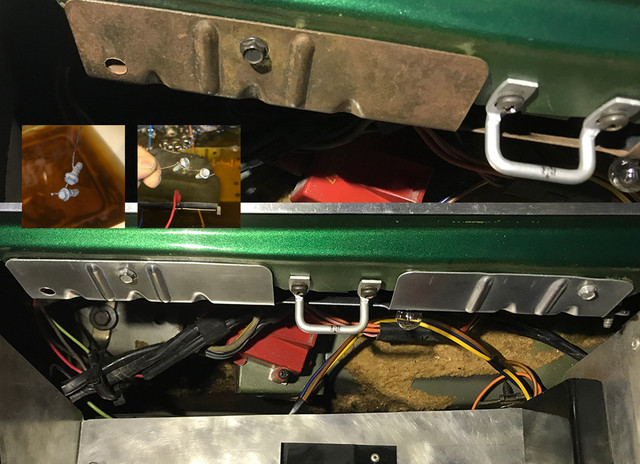

After months waiting, its the day I finally get to finish these brackets that I could spray!

Perfect timing!

The first brushes of the year are finally out!

Good kuz, I was using the autumn left overs

Before go search for hidden eggs, started by finishing the 2 headlight assembly parts.

Both were having lots of corrosion and passed the week in vinegar.

A wool massage in the sun, some cleanup and a few volts later, the first one was ready.

The last one, still having bits of rust in its deep pits, received few drups of elbow oil, and was done not long after that.

The second headlight assembly now plated, it was time for a group picture before next step.

After all this work to restore these parts to a rust free and protected condition.

It took less than a minute to ruin their shine with the first layer of epoxy!

Bye bye bling bling!

I wanted to have a thick layer applied today on the ones with the most scars, so I can sand them a bit tomorrow,

before they all receive a final coat.

After months waiting, its the day I finally get to finish these brackets that I could spray!

Perfect timing!

Last edited by a moderator: