@OzCoupe72

Yes, bought that thing for the mirrors. The 73 had only one chrome mirror and needs to have holes properly done for the passenger side. The 71 needs at least one to be replaced. Not a tool you use daily for sure, but always wanted have one.

[Reckon you'll have that beast painted soon and glad you've stuck to the original green]

"Soon" is a very flexible term

The green I'll use is not the original Ivy green. I've picked a version of it that is bits darker and using smaller aluminum particles.It should "draw" the lines with a greater contrast than the original paint could.

I can paint/finish small parts, and I can prep/prime parts, but the final exterior color+coat will be done at my local paint shop in a heated booth.

Most, like hood, deck lid etc... will/already have the inside painted by me.

---------------------------

Hot hot hot... whole week till yesterday was +- 38c / 100F

So hot it made me lazy on Saturday and did only little stuffs..

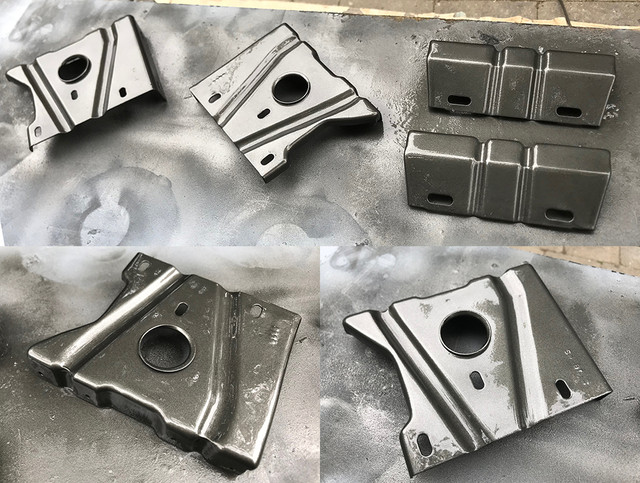

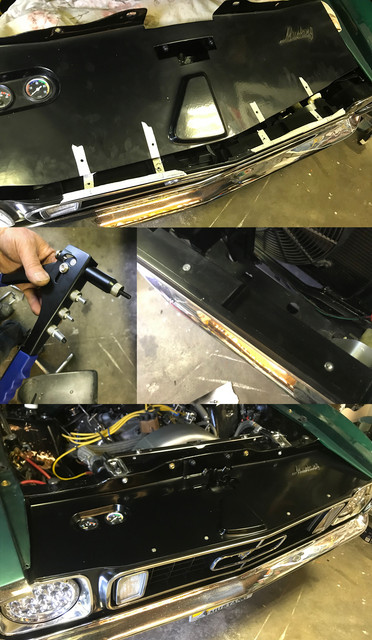

Under a totally must have parasol/umbrella, reassembled some of the parts that were plated and painted during past weeks.

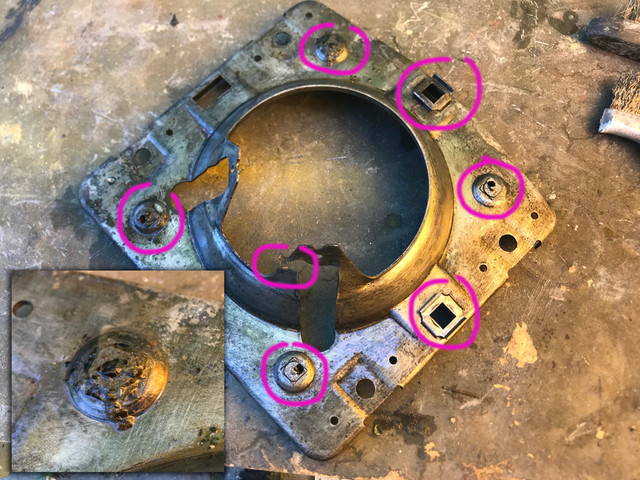

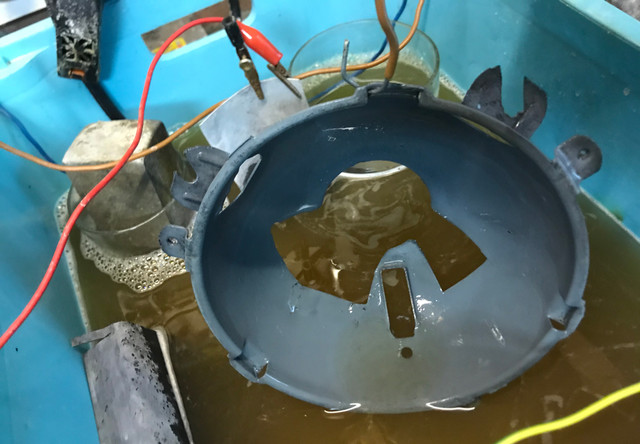

In middle the reassembly of the last set of headlight bracket, I saw I did not have a replacement spring for it as the 2 new ones I bought were already used. I had one spring in good shape, but it was corroded. So took a plating break and restored it.

After each and every bolt or screw was preturned and greased, eventually I was able to complete the last set! Yeeeeeeaaaaah!

After 4 rusty sets, I'm totally OD'd doing these and really do not plan do another set anytime soon!!

They might not be perfect, they might show some ancient scars here and there, but knowing the way they were (and knowing what's underneath the semigloss top coat).

I'm very please with the results!

Headlights brackets: DONE!

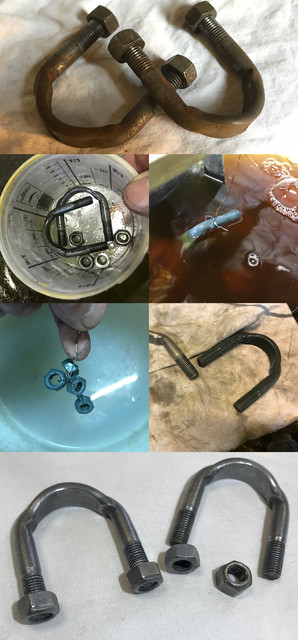

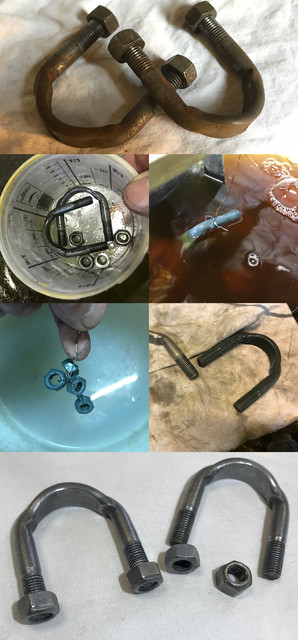

As temperature was unbearable, went looking for a small victim. These little guys, holding the driveshaft, made of high grade metal were just having small corrosion. So gave them some love and few bubbles later, they were as new.

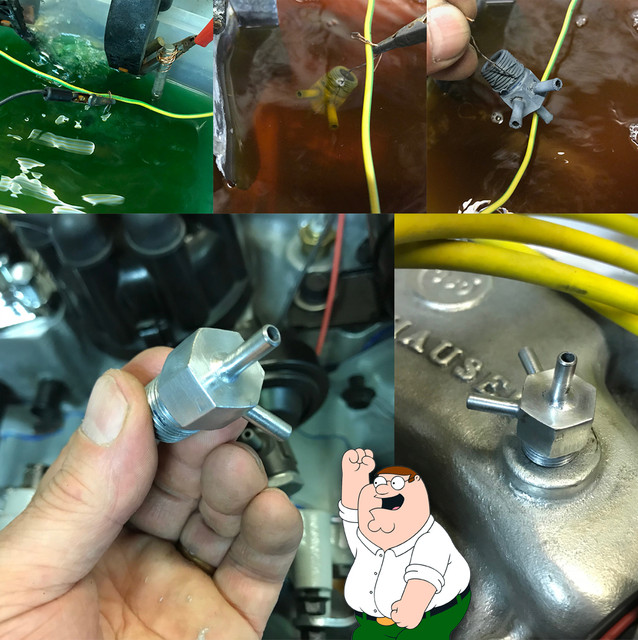

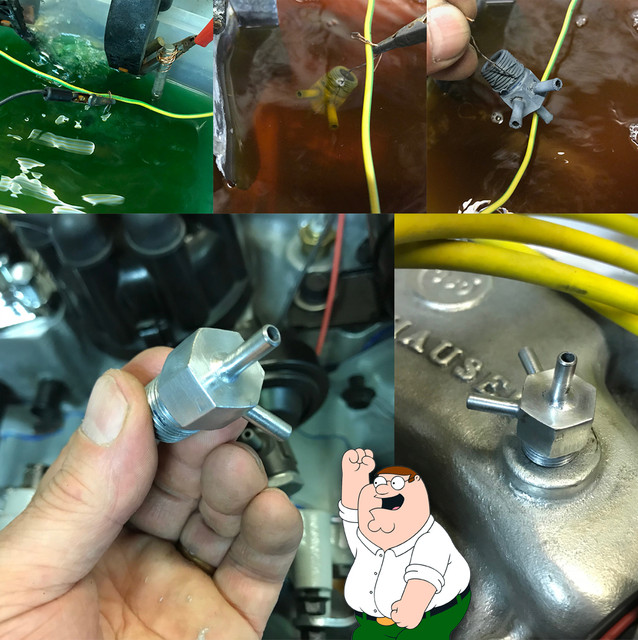

As I can't yet have a 2 tons engine hoist in the garage by lack of space, already ordered some of the stuffs I'll be needed, like a lift plate and some chains... The JEGGs plate was not fitting, so enlarged the holes just a bit and finally got on the engine.

That's when I saw to my horror, that the vacuum tree thingy cleaned up last year, started to show signs of corrosion. Totally unacceptable!!

Last year I didn't know how easy it was to plate and painted most other parts on the engine. But for that one, I thought the original protection was still good enough to avoid paint... I was wrong.

So gave that poor thing the love it needed and after a first layer of nickel, finished it with zinc. Back on the engine it was looking pretty again!

Then the sweaty me called it a day and went for a long cold shower.

Today's temp was 33c / 89F with bits of wind, so did the work I wanted to do on the 73 yesterday and then went back to the front fender. On the todo: close that "antenna" hole. This fender being the driver side, probably someone installed some extra antenna for some piece of high tech equipment (at the time). All I know is I've close the original one on the passenger side and wasn't planning to put back the rubber thingy that was closing it since at least 1989.

To make a round patch of this scale, I asked Mr Dremmel to help me. 2 tiny discs later, installed it with magnets and a piece of copper behind. Once welded and grounded, fixed two tiny holes that I've missed and dollied the region to have a seamless surface.

As my paint remover doesn't attack bondo and because I can't transform the garden (and occupants) into a white powdery landscape, sanding is out of order, so just like for the passenger one, I've used heat to remove it all. Discovered that at some point the body guy decided that it needed be done "right" with tin just like he did the hood corner, but he prolly decided 1/2 way that bondo was way faster... Then discovered other nice fixes, like a crease only asking for a hammer, that was instead hidden with 2 kilos of bondo. Same receipt for the region near the bumper, tho for that one, as to access it by behind is very hard when the fender is on, I can understand why he went for bondo vs fix.

Started hammer and dolly here and there, and was reminded by the garden occupants that the entire street population was in own gardens and that hammering could be a tad annoying. I totally disagreed on this, as Mustang metal sounds great! But it was late anyway, so cleaned up the mess... I'll prolly go make some noise this week when everybody's at work. Working home has its plusses

And so ended a very hot weekend.

To be continued...