Doc then you can clean and paint engine bay it will be worth it.Well, considering everything, I think I'll just push her back out of the garage and borrow a hoist from the school. With the troubles I'm having removing the dad blasted tranny cool, I'll need to pull it to swap the cams anyway. Not to mention the trouble with the harmonic balancer removal. Grrr.....

Doc

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How much does a 351C Block weigh

- Thread starter 73vertproject

- Start date

Help Support 7173Mustangs.com:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

True, true, true. My greatest fear is having to sell her as a great chassis and 1000 drivetrain pieces for $1000. Yikes!

Doc

Doc

We at this site will not let that happen.True, true, true. My greatest fear is having to sell her as a great chassis and 1000 drivetrain pieces for $1000. Yikes!

Doc

- Joined

- Jul 5, 2010

- Messages

- 6,687

- Reaction score

- 389

- Location

- Grand Rapids, MI

- My Car

- 73 Convertible

Even if we have to come to Winnemucca to assist with reassembly.We at this site will not let that happen.True, true, true. My greatest fear is having to sell her as a great chassis and 1000 drivetrain pieces for $1000. Yikes!

Doc

Last edited by a moderator:

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

Awww....

Bunch of knuckleheads....

I'll let you know as soon as I finally get the blasted harmonic dampener off, because that's about 80% of my stress right now.

Doc

Bunch of knuckleheads....

I'll let you know as soon as I finally get the blasted harmonic dampener off, because that's about 80% of my stress right now.

Doc

- Joined

- Jul 3, 2010

- Messages

- 726

- Reaction score

- 172

- Location

- The OC (California)

- My Car

- 31 Model A Station Wagon “Woody”

69 Mach 1 - 351C

30 Model A Cabriolet

96 Cobra Convertible

The best kind of engine crane is one that belongs to a buddy. Find a friend who has a engine crane you can borrow. My friends are always glad to let me "store" their engine cranes for them even if it is only for a few days/weeks.

Using the raftors sounds a bit too scary for me. I've already experienced a transmission falling on me, I really don't want to try an engine for size.

Using the raftors sounds a bit too scary for me. I've already experienced a transmission falling on me, I really don't want to try an engine for size.

$64.98

JH DESIGN GROUP Men's Ford Mustang Collage Black Zip Up Hoodie Sweatshirt (Large, CLG2-black)

Affordable Family Clothing

$99.99

Polished Rocker Panel Sill Plate Molding Kit with Clips Compatible with 1964-1966 Ford Mustang - Authentic Restoration for Classic Car Enthusiasts

Classic 2 Current Fabrication

$9.00

2016 Hot Wheels Vintage American Muscle 1970 FORD MUSTANG MACH 1 die-cast 4/10

Cards and Bobbles

$37.95

$39.95

2015-2024 Ford Mustang Bulge Acorn Lug Nuts & Wheel Locks Kit 14 mm x 1.50 Thread (Black)

West Coast Corvette / Camaro

$24.95

Ford Mustang Pony Racing Stripe 5.0 Muscle Shelby Long Sleeve T-Shirt Front Back Print-Black-Large

Giftware Shop Usa

$18.99

$19.89

Checkered Flag Men's Ford Mustang Cap Tri-Bar Pony Logo Adjustable Black Hat

BS STORE LLC

$37.17

$55.00

The Complete Book of Ford Mustang: Every Model Since 1964-1/2 (Complete Book Series)

Amazon.com

$29.70

Ford Mustang, Mach 1, GT, Shelby, & Boss V-8 (64-73) Haynes Repair Manual

Haynes Repair Manuals

$59.98

JH DESIGN GROUP Men's Mustang Logo Hoodie Full Zip Up Black Hooded Sweatshirt (X-Large, Black)

Affordable Family Clothing

$13.75

$16.39

Ford Mustang: Trivia & Fun Facts Every Fan Should Know About The Great American Icon!

Amazon.com

$39.99

Lucky Ride Ford Hoodie Legend Lives Mustang Pony (Pocket) Full Zip Sweatshirt, Red, Medium

Giftware Shop Usa

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

LOL... I agree. I'm pretty sure I can borrow one. I'll let you know.

Doc

Doc

Doc I would lend you mine if you where closer. MikeLOL... I agree. I'm pretty sure I can borrow one. I'll let you know.

Doc

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

I know you would, Mike. Instead, I'll be asking for you to share your wisdom once I get 'er pulled and start replacing parts and such while pulling my hair out.Doc I would lend you mine if you where closer. MikeLOL... I agree. I'm pretty sure I can borrow one. I'll let you know.

Doc

Doc

Maddog9776

New member

- Joined

- Feb 9, 2011

- Messages

- 2

- Reaction score

- 0

- Location

- Plainfield, IL

- My Car

- 1971 Mach 1

Grabber Lime

351C, 3V heads

Mutha-Thumpr cam.

Jumping on this string a little late, but in case anyone is still interested...

I just rebuilt my 351C this last summer and weighed the bare block. It was 180Lbs. Full long block with aluminum heads and intake was about 400lbs. If you have cast heads (add 70lbs) and cast intake (add 30lbs) you're looking somewhere around 500lbs +/- a few.

I just rebuilt my 351C this last summer and weighed the bare block. It was 180Lbs. Full long block with aluminum heads and intake was about 400lbs. If you have cast heads (add 70lbs) and cast intake (add 30lbs) you're looking somewhere around 500lbs +/- a few.

- Joined

- Sep 13, 2010

- Messages

- 7,933

- Reaction score

- 440

:goodpost: thanksJumping on this string a little late, but in case anyone is still interested...

I just rebuilt my 351C this last summer and weighed the bare block. It was 180Lbs. Full long block with aluminum heads and intake was about 400lbs. If you have cast heads (add 70lbs) and cast intake (add 30lbs) you're looking somewhere around 500lbs +/- a few.

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

Just dragging up an old thread that had a big influence on me and my restoration of the 73vertproject. Mach71351c - if you're out there (and I trust you are) - your encouragement is missed. To all, I'm preparing for the summer month-long hiatus to Montana. More in another post. I hope to be heading out on June 14. Eight days until school is out! dancebanana::chili::dancebanana

This was the original post that put everything into perspective with this website. So, I guess it's Mike's fault after all.We at this site will not let that happen.True, true, true. My greatest fear is having to sell her as a great chassis and 1000 drivetrain pieces for $1000. Yikes!

Doc

Last edited by a moderator:

Finmach

Well-known member

- Joined

- Jul 10, 2012

- Messages

- 241

- Reaction score

- 2

- Location

- Finland

- My Car

- '72 Mach 1. Ford Racing 460+TKO600+Moser M9 4.11 DL

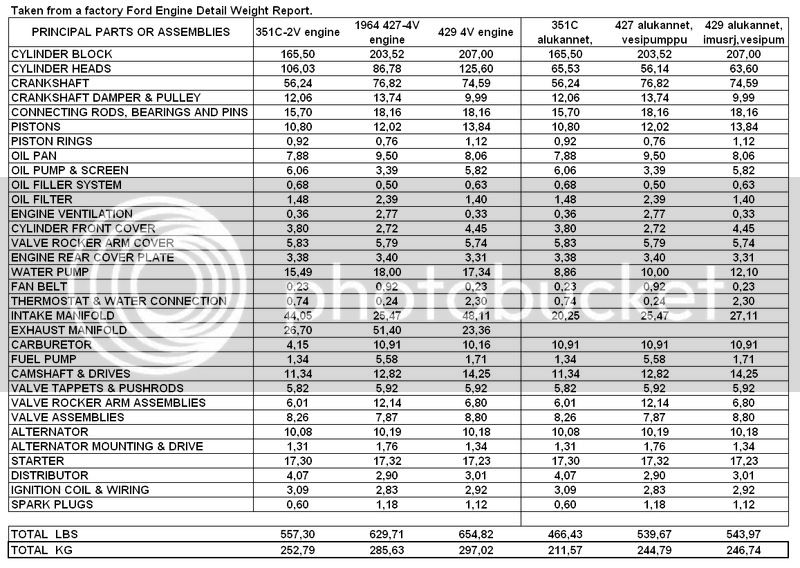

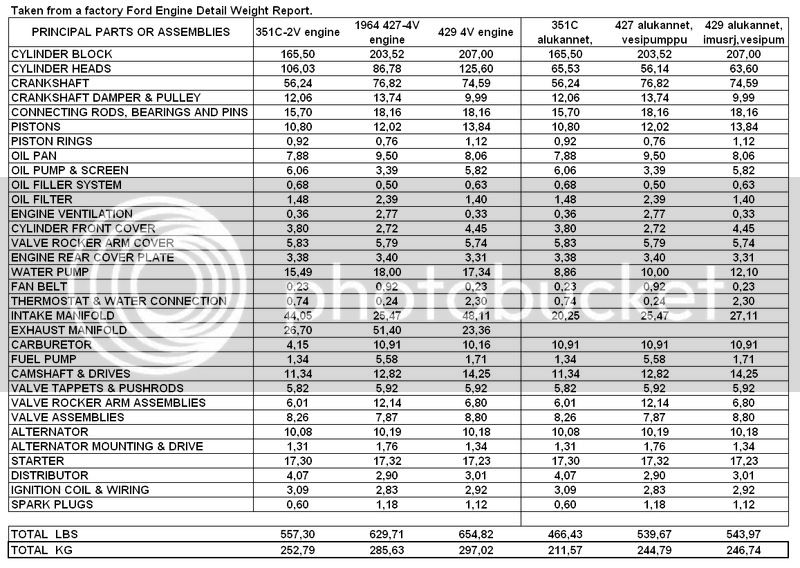

I bumped in a couple of years ago to a Ford Engine Weight Detail reports. According the reports I combined three engine weights to the same "page" so they can be compared easily.

Left side has the standard 351c 2v, 427 FE and 429 thunder jet. The right colums there are used aluminium heads, aluminium intake and aluminium waterpump for all the three engines. I had my friends to scale all the parts, like a true FE waterpump&manifold, cleveland parts, I scaled 429 parts etc. Everything is pretty close if the factory report is correct though. Feel free to comment!!! Standard 4v 351w is about 9 lbs lighter than the 351c 2V. There is commonly a false number for the 429/460 weight, its allmost allways somewhere +700 lbs. That weight is incorrect, it is though taken from the same engine detail reports but it includes everything that the engine needs to work, like radiotor, fluids, hoses... you get the picture?

Left side has the standard 351c 2v, 427 FE and 429 thunder jet. The right colums there are used aluminium heads, aluminium intake and aluminium waterpump for all the three engines. I had my friends to scale all the parts, like a true FE waterpump&manifold, cleveland parts, I scaled 429 parts etc. Everything is pretty close if the factory report is correct though. Feel free to comment!!! Standard 4v 351w is about 9 lbs lighter than the 351c 2V. There is commonly a false number for the 429/460 weight, its allmost allways somewhere +700 lbs. That weight is incorrect, it is though taken from the same engine detail reports but it includes everything that the engine needs to work, like radiotor, fluids, hoses... you get the picture?

Last edited by a moderator:

- Joined

- Aug 7, 2010

- Messages

- 5,074

- Reaction score

- 10

- Location

- McDermitt, NV

- My Car

- 1973 Convertible H Code, 351C 2V FMX

What a great chart, Finmach. Would you mind if we post it in the Data section of this website? Thanks for posting it!

Finmach

Well-known member

- Joined

- Jul 10, 2012

- Messages

- 241

- Reaction score

- 2

- Location

- Finland

- My Car

- '72 Mach 1. Ford Racing 460+TKO600+Moser M9 4.11 DL

Feel free to use it! I am honored. I'll update it someday with English text at the right colums, so you can replace this existing one with the local language!! I am happy if the chart helps someone!What a great chart, Finmach. Would you mind if we post it in the Data section of this website? Thanks for posting it!

You might also notice that I left the headers out of the right colums due to wide variety of headers.

Last edited by a moderator:

- Joined

- Jan 6, 2013

- Messages

- 399

- Reaction score

- 7

- Location

- Birmingham, AL

- My Car

- 71 Mach 1. Originally 2V but going 4V soon!

I like this. Not planning on yanking a ton of motors, just one. Take the 4x4's out if needed when done. Nice idea Q.Doc,Thanks, guys, for the info. I'll let you know what I decide, with scary pictures if it comes to that.

Doc

You can use a rafter, most rafters are 2x8's(I'm a contractor & have designed & built many structures) The key question is the SPAN of the rafter...Heres a caculator that will help

http://www.decks.com/Calculators/JoistSpan.aspx

All you need to do is double up the rafter you plan to use... you only need to double up the width of the car & make sure the the 4x4's are placed under the doubled up rafter..Then use 2 lag bolts every 12 inches....Then get 2-4x4's ..2-cap baseshttp://www.strongtie.com/products/connectors/BC.asp#gallery

Run the 4x4's on each side of the car from the floor up to the rafter & screw to the rafter with deck screws. You will have no problem hanging that motor since all the weight will now be transfered to the 4x4's and floor.

Scott

2x4 doublers could be stronger, lighter and easier to set up as jack studs. probably cheaper to buy and lighter to transport home. Make it corners if you really want strength. And screws come out easier than nails if you plan to break them down afterwards. Did some framing when i when a younger man.

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 79

- Views

- 5K

- Replies

- 86

- Views

- 8K

- Replies

- 30

- Views

- 4K

- Replies

- 14

- Views

- 2K

Latest posts

-

-

1973 Convertible Project: Coupe Parts Swap Begins

- Latest: Steve McMahan

-

-

-

Personalized Plates Lets see how may different one are out there.

- Latest: Nightbeacon