- Joined

- Aug 14, 2014

- Messages

- 4,617

- Reaction score

- 1,650

- Location

- Madison, WI

- My Car

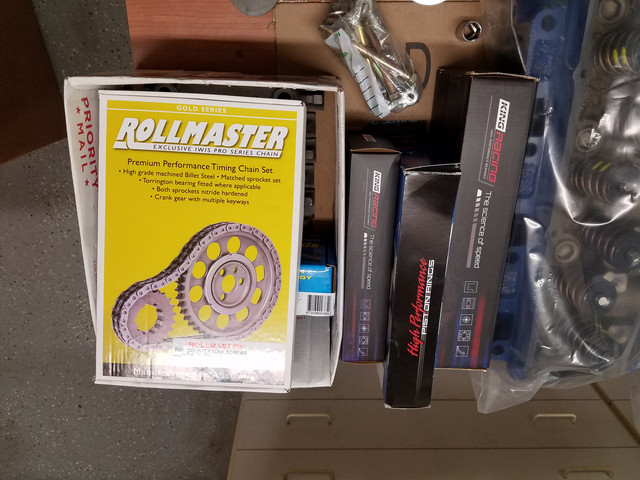

- 1971 Mach 1 w/408C stroker

Plans for this next few days:

-Adjust the booster master cylinder push rod. Any tips on how to do this?

-Clean and undercoat the transmission tunnel before the new TKO600 goes in.

-Adjust the booster master cylinder push rod. Any tips on how to do this?

-Clean and undercoat the transmission tunnel before the new TKO600 goes in.