- Joined

- Aug 14, 2014

- Messages

- 4,617

- Reaction score

- 1,650

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

I am proud to say that I tested the engine and run great. The only issue I had during testing was with the old carburetor. Silly me thinking that I could use an old carburetor that has been sitting for two years. The secondaries float was not sealing so gasoline kept flooding. I ended up capping the gas supply to the secondaries so I can test the engine. Since I had no radiator I ran it for a short time until the thermostat opened. I was so busy taking care of stuff during that time that I forgot to shoot a video.

One issue I noticed after the test was that while turning the engine by hand I kept hearing this grinding noise. It worried me for a while until I figured out it was the flywheel rubbing against the engine back plate (block plate). I have read about this in the past, but I have forgotten. Because the oil pan sticks out slightly at back it doesn't allow the back plate to sit flush causing it to rub against the flywheel. Now I just have to remove the flywheel and grind a smiley face on the back plate so it sits flush. I had installed the flywheel bolts with red Loctite so it will be fun.

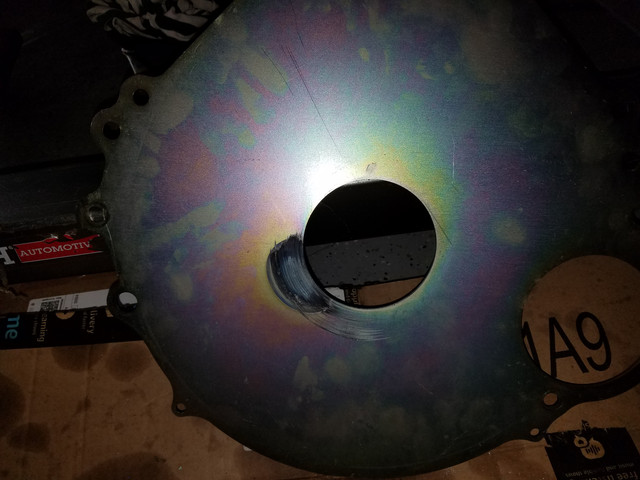

Here is the block plate after being ground against the flywheel:

Here is the flywheel:

Since the block plate is aluminum and the flywheel is steel, there was very little damage to the flywheel. What I think it happened is that the heat generated started melting the aluminum and breaking it into the flywheel. A soft touch with the flap wheel took care of it. It now looks shiny with little to no steel material removed.

I now ground a groove on the block plate to allow for a flat fit of the bellhousing. Today I will test for flatness.