- Joined

- Aug 8, 2018

- Messages

- 413

- Reaction score

- 216

- Location

- California

- My Car

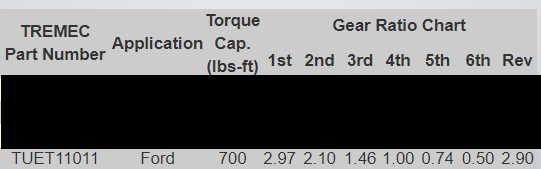

- 72 Sportsroof - 351C-4V, Fitech EFI, T56 Magnum 6 Speed

We've been putting together a '72 fastback 351C 4V project for a few months now. We got the car with no trans installed but included a new in box Tremec T56 Magnum Speed manual. Not my first choice for a trans, but it's a great trans and it was part of the deal so we went for it. So we've spent the last few months converting from auto to manual and finally have it running and driving.

Now that we have it going it seems pretty clear that it is geared too tall. I can run around my neighborhood in 1st gear or drive at 60 in 3rd . It feels like a car that's meant to cruise at 90 vs get up to 60.

This isn't going to be a race car, but we want it to be quick off the line and still be able to cruise on the freeway, which I think it is the point of the 6 speed manual. I think the car has a 3.25:1 rear end right now.

Appreciate any input on rear end gearing to get this thing to be quicker off the line while still being driveable on the freeway.

Now that we have it going it seems pretty clear that it is geared too tall. I can run around my neighborhood in 1st gear or drive at 60 in 3rd . It feels like a car that's meant to cruise at 90 vs get up to 60.

This isn't going to be a race car, but we want it to be quick off the line and still be able to cruise on the freeway, which I think it is the point of the 6 speed manual. I think the car has a 3.25:1 rear end right now.

Appreciate any input on rear end gearing to get this thing to be quicker off the line while still being driveable on the freeway.

Last edited by a moderator: