Yeah, I never thought to ask him that about the cam and whether he installed it that way. I want to say he didn't. He wanted this motor to be very similar to a 71 Boss 351.Big red mach 1,Yes sir, this is Eddie's old car. I have been chatting with him outside of this site. This is where I've gotten the list of specs that I do have from. He sold the car in 2016 to a "collector" who for the most part just let the thing sit. That's how the story goes, but I dunno.Isn't this Eddie's (FastE) old Mach? I can tell you from personal experience when he had it... it RAN! I believe there was another owner in the mean time.

Eddie may be a good resource for specifics on the combination.

What I do know from Eddie is that this car under his care for 42 years, was always in top shape and ran like a scalded dog. So he's been a bit surprised to hear of the issues I've been having. He's a good guy, and a great person to talk to about what the car has in it, but without him here looking at it, he's just guessing like the rest of us. again, he's surprised that it's running poorly at all.

At this point you will probably get more from FastE than you will get from the rest of us.

Would ask, was cam installed 4 degrees retarded and how much vacuum was he seeing at hot idle.

Intake manifold leak would make sense, as it could have started to leak over time, could just check and see if any of the bolts have worked loose, carb spray (or propane) will only tell you if it is sucking air from external, not internal.

Would not rule out faulty carb work either.

Boilermaster

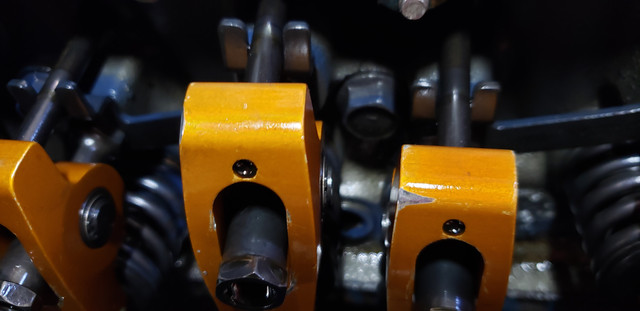

I personally believe that the bulk of my issue is in fact the low vacuum issue. I also believe that the lifter prelaod is probably not correct. Symptoms of improper adjustment are hard starting, very rough abnormal idle, low vacuum. I have all 3. Also, when I brought the car home, everything on this motor was loose. Valve covers loose, intake manifold loose, tree on back of manifold loose. I'm talking all finger tight. All have since been tightened back up and in the case of the intake properly re torqued. I have to believe those nuts on the rockers aren't right also. I think the mission this weekend is to do 3 things. 1. Check for a leak at the intake as you have suggested. 2. Re-adjust the lifter preload, hope for better idle and more vacuum. 3. Compression test as Stanglover suggested. I'll do this after the preload adjustment. 4. I will check fuel pressure into the carb as another member mentioned that I am running dual fuel pumps and could be ending more fuel to the carb than the Holley wants.

I'll post my findings.

Last edited by a moderator: