- Joined

- Jul 21, 2012

- Messages

- 3,240

- Reaction score

- 16

- Location

- South Florida

- My Car

- '71 Mustang Mach 1 M-code "Soylent Green"

'69 Plymouth Valiant 100

'68 Plymouth Satellite

I'm not sure how many of you have worked with the current rear crossmember reproduction - but for those who have, I'd appreciate your advice with the following problem:

The rear edge of the rear frame crossmember - according to what I've seen - is supposed to lie on the same plane as the taillight panel, allowing the taillight panel to butt up to it from the back. Simultaneously, the panel sits on the same plane as the lower halves of each quarter panel, which fit on the front edge.

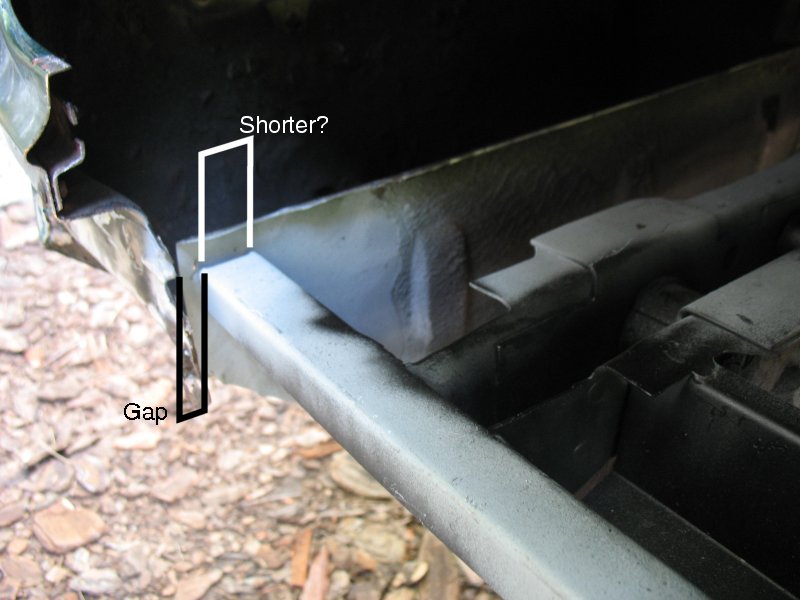

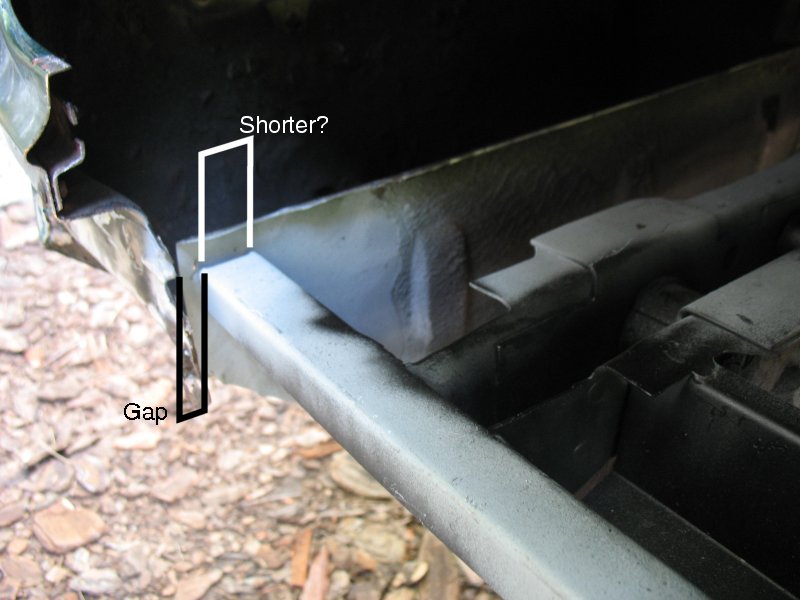

However, the reproduction crossmember rear lip sits a quarter inch too far forward (test fits of the trunk result in the trunk hanging over the crossmember by the same amount), despite the crossmember having been welded directly to the original left framerail end. The framerail is unchanged from stock and is undamaged.

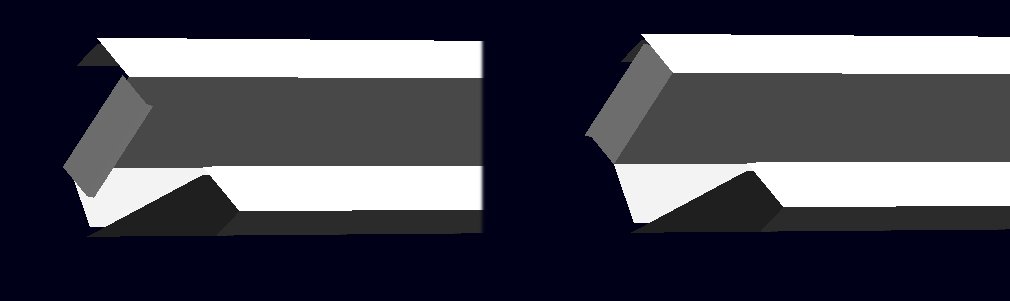

Though I do not have the scrap that I removed from the car, I did bring up a photo from the job - wherein the original crossmember appears to be 1/4" longer than the reproduction:

Now, if I push the quarter extension and dropoff together, I can close the gap, though the trunk still sticks out about 1/8", which is enough to keep the taillight panel from fitting.

Has anyone experienced this before with one of the repops? If so, what did you do to correct it?

-Kurt

The rear edge of the rear frame crossmember - according to what I've seen - is supposed to lie on the same plane as the taillight panel, allowing the taillight panel to butt up to it from the back. Simultaneously, the panel sits on the same plane as the lower halves of each quarter panel, which fit on the front edge.

However, the reproduction crossmember rear lip sits a quarter inch too far forward (test fits of the trunk result in the trunk hanging over the crossmember by the same amount), despite the crossmember having been welded directly to the original left framerail end. The framerail is unchanged from stock and is undamaged.

Though I do not have the scrap that I removed from the car, I did bring up a photo from the job - wherein the original crossmember appears to be 1/4" longer than the reproduction:

Now, if I push the quarter extension and dropoff together, I can close the gap, though the trunk still sticks out about 1/8", which is enough to keep the taillight panel from fitting.

Has anyone experienced this before with one of the repops? If so, what did you do to correct it?

-Kurt

Last edited by a moderator: