- Joined

- Aug 14, 2014

- Messages

- 4,593

- Reaction score

- 1,630

- Location

- Madison, WI

- My Car

- 1971 Mach 1 w/408C stroker

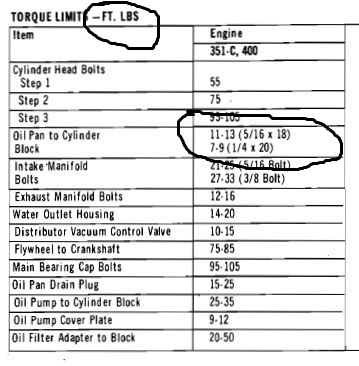

I repeated the process with the Milodon gasket and less torque. I was at about 6 and 8 in torque. Let's see how they do in actual service.

Something I noticed is that the front and rear rubber pieces were a lot longer in the gasket from the Mr.Gasket set than those that came with the Milodon. The Milodon rubber pieces fit perfectly while the longer ones from Mr. Gasket were not a good fit because being too long. Look at the picture. The difference in length was significant.

Something I noticed is that the front and rear rubber pieces were a lot longer in the gasket from the Mr.Gasket set than those that came with the Milodon. The Milodon rubber pieces fit perfectly while the longer ones from Mr. Gasket were not a good fit because being too long. Look at the picture. The difference in length was significant.