Aus73Mach1

Well-known member

- Joined

- Aug 5, 2019

- Messages

- 173

- Reaction score

- 149

- Location

- QLD Australia

- My Car

- 1973 Mach 1 Sports Roof.

Q code. 351-4V

C6 Auto, 3.25 Rear Axle, AC, Power steering.

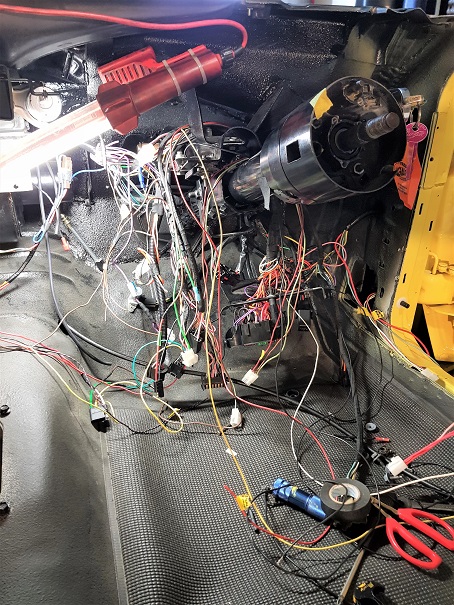

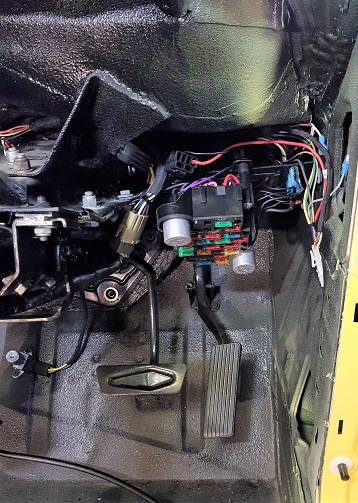

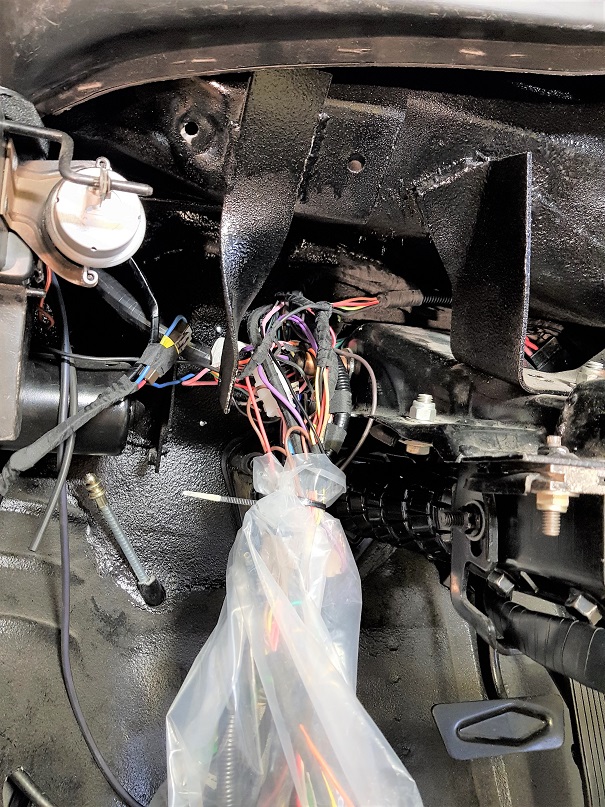

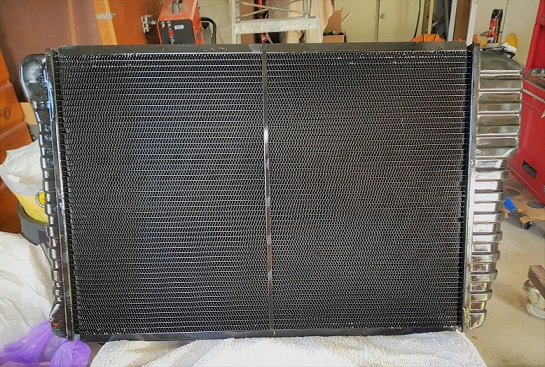

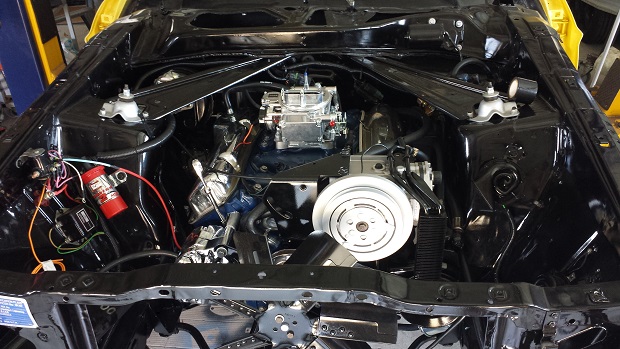

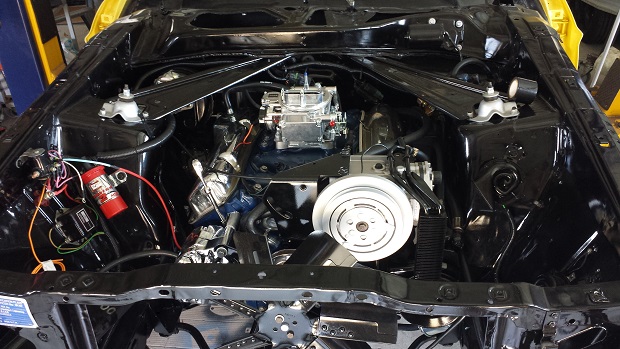

Some more progress over the last few weeks. Concentrating mainly on getting the engine bay finished as it's easier to reach and fit hoses, etc with the guards off.

Engine Bay

New AC compressor.

Headers back from ceramic coating and fitted.

Some of the other items finished.

Exhaust brackets repaired.

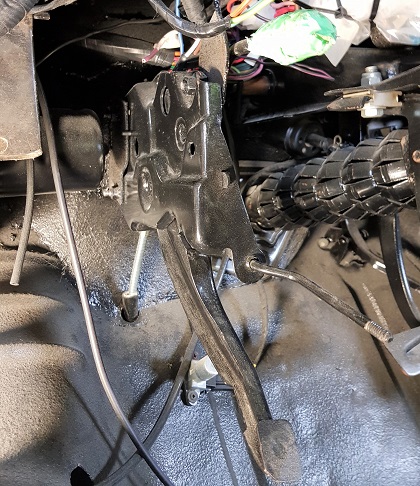

Kickdown rod was missing so a new one made from aluminum tube.

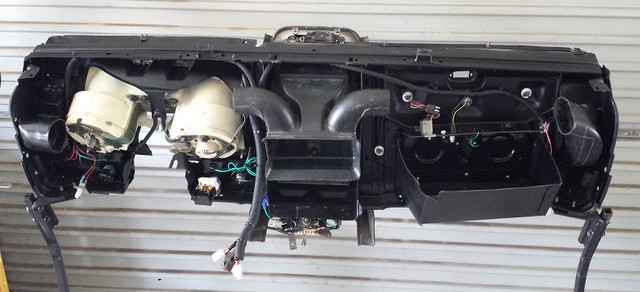

Instrument cluster refurbished.

Engine Bay

New AC compressor.

Headers back from ceramic coating and fitted.

Some of the other items finished.

Exhaust brackets repaired.

Kickdown rod was missing so a new one made from aluminum tube.

Instrument cluster refurbished.