Got the car up in the Air and have found many more problems.

Damaged rear passenger floor pan,

Front suspension strut crossmember bent.

Someone tried to weld up the crossmember!

I have purchased a replacement Crossmember and that should be fitted in the next couple of weeks.

The Weatherstripping on the car is in a very poor state and I have also purchased the parts needed.

One thing many of the companies don't tell you is that there are actually 2 weatherstrips on the outside of the door, the upper weatherstrip normally comes in the new beltline kit, but the lower one is NOT included! This seems nuts to me.

So I managed to find the correct part from NPD.

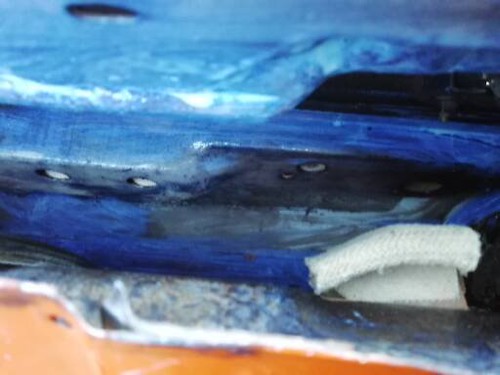

I have made a start on Stripping the doors, clearing out surface rust, vacuuming out the crud and treating the interior of the door and quarter panel with water based rust converter I purchased off eBay. Once this is fully dry (and the weather improves) I will spray over this with Grey Zinc primer.

I have also started rust proofing the inner quarter panels

Before clearing off the crud,(you can see the moisture build up)

After rust treatment

I have also had to remove the passenger side roof drip rail as that is damaged and I now need to find a new one

Again I will give the rust treatment a blow over with Zinc Primer prior to reassembly.

Now if anyone can help me with advice on the correct sealants and reassembly of the roof drip rails and weatherseals I would appreciate it

I will most likely have to order everything from the USA.

Now I needed to do something to cheer me up actually Fitting something on the car (rather than keep removing stuff), so I purchased a interior glove box light from an earlier mustang.

I had to make the empty hole on the glove box frame a little bigger using a step drill and 1st fixed the new light switch and bulb.

2nd job was to fill the empty hole above the centre console where the infamous Map light should be (depending on which model car you have,

my car is a basic 302 so it did not come with the light).

I had seen posts from some old members on here but I did not get any reply on seeking a replacement light, I had seen one on eBay for over $238.00 (which was nuts) So I decided to make my own.

I purchased a Hella interior light (which I think is mercedes and features a 3 position switch) for $9.00 then found an old bit of black plastic and cut the recess for the light to fit, then I shaped the plastic to fit the shape of the centre console. It's not finished yet as I have to clean up the black plastic to get a good finish on it, I also have to wire it up, but I am pleased with the result so far