I don't know how deep those Allen bolts go into the block, but it's not very much (less than or up to 3/8", if I remember correctly). With them inserted and thread-locked, there should be no danger of oil leaking or being obstructed in the channel where they might breach.

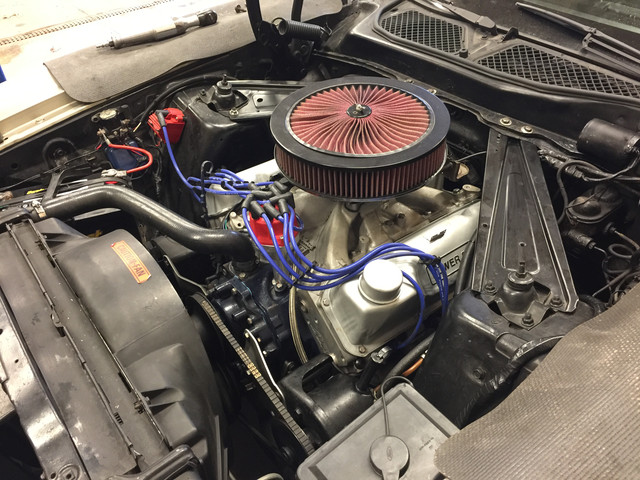

As well, the raised channels on the spider itself correspond with the existing holes in the top of the block to aid in the oil flow back to the inlets. As you can see in the 'before' picture of my engine, the holes under the center spine of the spider are where the oil finds its way back into the engine. If you block them with fasteners for the lifter spider, then you probably will impede the return flow of the oil (by blocking off the path for the oil to return).