Ballaratcastle

Well-known member

- Joined

- May 29, 2018

- Messages

- 161

- Reaction score

- 0

- Location

- New Zealand

- My Car

- 1973 Mustang Convertible. Just imported from the USA as an unfinished project.

[url=https://ibb.co/gXU4Qy][img]https://preview.ibb.co/f0tW5y/Mustang.jpg[/img][/url]

Hi All

A newbie to mustangs. I recently imported an unfinished project from the states.

Our certification process to register the vehicle for the roads in NZ is rather complex and if the vehicle is tagged at the border as having had repairs it requires a repair certifier to inspect the vehicle.

Sadly my certifier (who is a good guy) discovered my 73 convertible had suffered a frontal impact some time in its life and had been repaired badly. The US owner I bought the car from had the car panel and painted to the tune of 12K 5 yrs ago. As he was away overseas and left it to the restorers, had no idea that the drivers chassis rail (you call it a frame rail) had a distortion where the crumple hole is and we have now discovered when we went to put it on a chassis straightener (Car-o-liner) that it is cracked right through and everything is way out of alignment. (That explains why the drivers fender was bolted 1cm further forward with redrilled holes.

The panelbeater recommended that the cost of unstitching the aprons and then welding on new frame rails and rewelding aprons was not that cost effective as opposed to getting a donor front half and welding the frame rails back on the fire wall.

While searching parts websites I see Dynacorn have a complete Shock Tower Apron Frame rail assembly for between $650-700 usd for each side.

On the CJ pony parts website there is only one review saying it was a crap fit and the rear aprons had to be unstitched then cut down and rewelded once the frame rails were welded in place. He complained Dynacorn were not forthcoming in assisting his repairer and it cost him an extra $800 in labour. As this review was over a year ago I wonder if they took the advice on board and adjusted their tooling of the aftermarket panel. I emailed Dynacorn and have had no reply. I have seen reviews of the similar assembly for a 65-68 model where they said theirs was a perfect fit.

So my question is have any of the members had to fit one of these as well and not had the same problems. Maybe the reviewers firewall was out of alignment? Who knows.

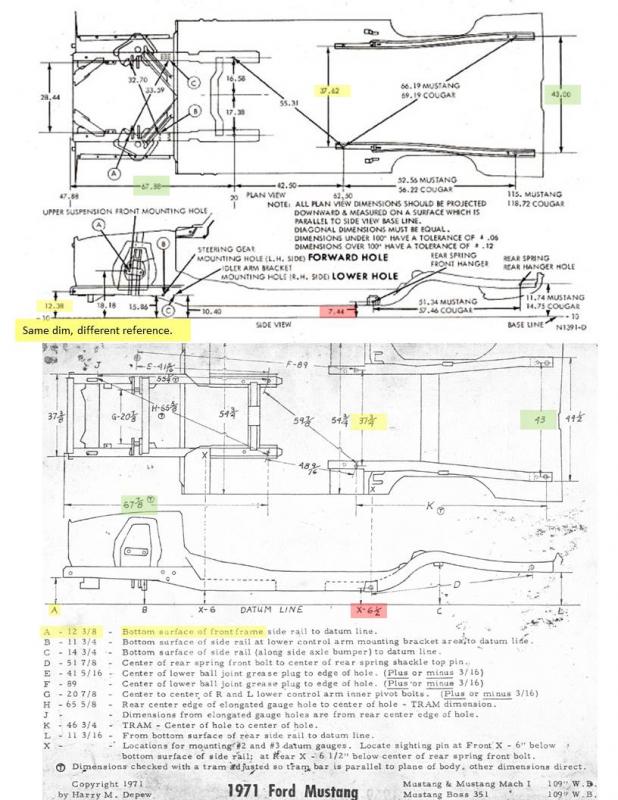

My second question follows on from this. The panelbeater has absolutely no measurements to go off having not done a 73 mustang. Does anyone have any knowledge who might be able to supply the specs for the car so they can align everything properly.

Cheers

Steve

A newbie to mustangs. I recently imported an unfinished project from the states.

Our certification process to register the vehicle for the roads in NZ is rather complex and if the vehicle is tagged at the border as having had repairs it requires a repair certifier to inspect the vehicle.

Sadly my certifier (who is a good guy) discovered my 73 convertible had suffered a frontal impact some time in its life and had been repaired badly. The US owner I bought the car from had the car panel and painted to the tune of 12K 5 yrs ago. As he was away overseas and left it to the restorers, had no idea that the drivers chassis rail (you call it a frame rail) had a distortion where the crumple hole is and we have now discovered when we went to put it on a chassis straightener (Car-o-liner) that it is cracked right through and everything is way out of alignment. (That explains why the drivers fender was bolted 1cm further forward with redrilled holes.

The panelbeater recommended that the cost of unstitching the aprons and then welding on new frame rails and rewelding aprons was not that cost effective as opposed to getting a donor front half and welding the frame rails back on the fire wall.

While searching parts websites I see Dynacorn have a complete Shock Tower Apron Frame rail assembly for between $650-700 usd for each side.

On the CJ pony parts website there is only one review saying it was a crap fit and the rear aprons had to be unstitched then cut down and rewelded once the frame rails were welded in place. He complained Dynacorn were not forthcoming in assisting his repairer and it cost him an extra $800 in labour. As this review was over a year ago I wonder if they took the advice on board and adjusted their tooling of the aftermarket panel. I emailed Dynacorn and have had no reply. I have seen reviews of the similar assembly for a 65-68 model where they said theirs was a perfect fit.

So my question is have any of the members had to fit one of these as well and not had the same problems. Maybe the reviewers firewall was out of alignment? Who knows.

My second question follows on from this. The panelbeater has absolutely no measurements to go off having not done a 73 mustang. Does anyone have any knowledge who might be able to supply the specs for the car so they can align everything properly.

Cheers

Steve

Last edited by a moderator: