- Joined

- Sep 12, 2015

- Messages

- 7,643

- Reaction score

- 2,767

- Location

- SW Ontario

- My Car

- 1971 Mustang Mach 1, M code, 4 speed.

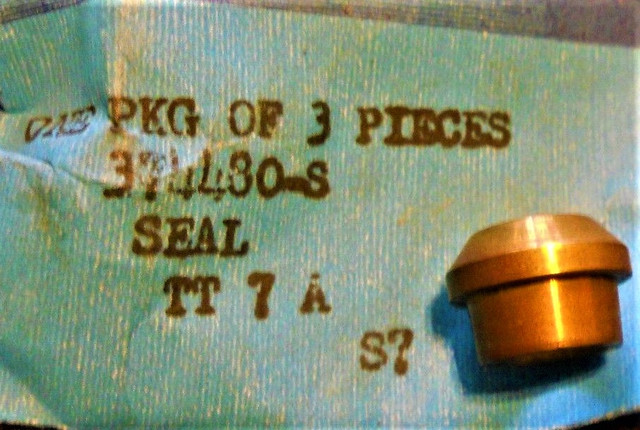

For those following this post, I just received the NOS seat kits I ordered, C5AZ3D728-A from Green Sales in Cincinnati Ohio. I was surprised to find it contains not only the inlet seat and check valve components, but also the outlet port seat. There are actually 2 different ones of these to replace an older style, depending on what the box had in it. I also ordered 2 x 374480-S seats for the outlet separately, so now I have spares.

Now I have all the components I need to rebuild both my PS boxes (or PS gear). I will regrind the sector shaft next week. Lucky me got called in to work for a week!!

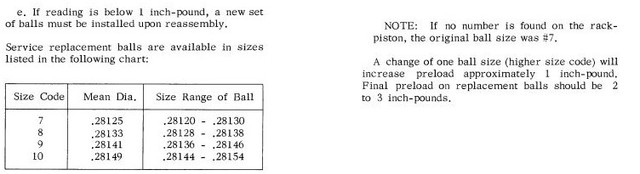

I will be trying out different ball size combinations from .2805" to .2814" (and in between) to find the best preload as specified in the Ford manual. When done, I'll update my findings, but for now, it's on hold until it I get inspired to work out in the cold workshop...……. or wait for spring!

The other thing I'm pondering is to rig up a test stand, but for that I'll need a PS pump and an electric motor. Any thoughts?

Geoff.

Now I have all the components I need to rebuild both my PS boxes (or PS gear). I will regrind the sector shaft next week. Lucky me got called in to work for a week!!

I will be trying out different ball size combinations from .2805" to .2814" (and in between) to find the best preload as specified in the Ford manual. When done, I'll update my findings, but for now, it's on hold until it I get inspired to work out in the cold workshop...……. or wait for spring!

The other thing I'm pondering is to rig up a test stand, but for that I'll need a PS pump and an electric motor. Any thoughts?

Geoff.