- Joined

- Sep 16, 2017

- Messages

- 80

- Reaction score

- 2

- Location

- Australia

- My Car

- 1973 Mach 1 - matching numbers, 25,000 miles Eleanor look-a-like

[url=https://ibb.co/mvrntk][img]https://preview.ibb.co/bG8YYk/1_lr.jpg[/img][/url]

[url=https://ibb.co/dwgntk][img]https://preview.ibb.co/fEZ7tk/2.jpg[/img][/url]

[url=https://imgbb.com/]picture hosting websites free[/url]

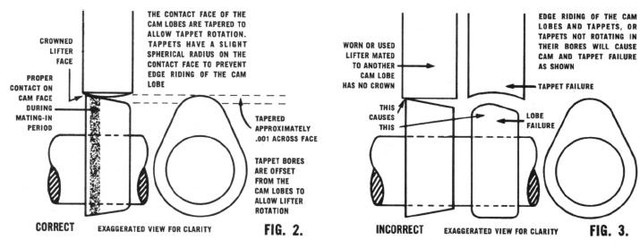

Just pulling apart the 351C-2V from my '73 Mach 1. Just wondering which parts needed be kept in the correct numbered order when you're doing a full rebuild. I know it's pretty critical when just doing a partial rebuild i.e. head gasket, but is it so important when you're doing everything (at least everything that is not in vgc)?

For example, I would imagine we need to keep the tappet order the same and note the top Vs bottom, but would not have thought it would matter with the pushrods or rocker arms?

Appreciate your time on this.

(PS Sorry if there is already a thread on this - please direct me to it.)

For example, I would imagine we need to keep the tappet order the same and note the top Vs bottom, but would not have thought it would matter with the pushrods or rocker arms?

Appreciate your time on this.

(PS Sorry if there is already a thread on this - please direct me to it.)

Last edited by a moderator: