Here's your book:

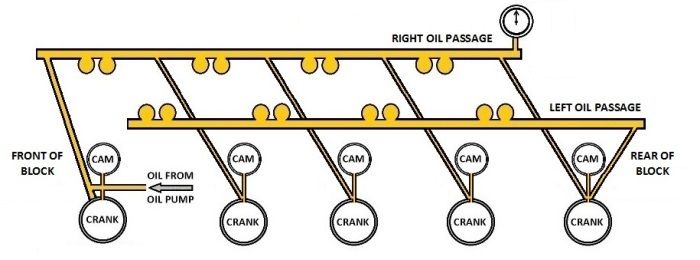

"The oil pump bypass spring serves as the effective limiter for peak oil pressure when the engine is cold or at high RPM. The cumulative area of all bearing and valve train clearances in the engine defines the pressure at any time below peak."

This is taken directly from Ford Engineering circa 1949. It is also what I have observed and understood over the years. Oil pumps have not changed in basic design since 1949.

So when the engine is cold and the oil is thick the pump will dump some of the pressure because the oil is too thick to all physically move through the pump. Without the bypass something would have to break. Hydrolic lock.

At high RPM the shear velocity of the oil moving through the system causes the pump to bypass because again it all physically can not move through the pump. Without the bypass something would have to break. Again, Hydrolic lock.

In between cold and high rpm your engine has thin oil that is not moving to fast so the only thing that controls the psi under these conditions is how tight, loose, or how blocked the oiling system is.

The bypass in the oil pump is actually there mostly to protect the oil pump.

If your oiling system is blocked at any point and the oil is thin enough to pump and your are not at high RPM's the oil pump will just keep on pumping and something else has to give and that typically is the oil filter.

Now you may think that the filter also has a bypass and it does. But is is a differential based bypass so if the pressure is 400 psi on both sides then it will not bypass but will just burst.

It is possible to get multiple bad pumps in a row but it is unlikely.

It is very possible to screw up a Cleveland oil system modification and get a passage blocked. I have done it wrong and I have had a filter burst.

Again - If that happens and you are using multi weight oil, then at start up the oil is thin enough to pump and you are not at high RPM so the oil pump just keeps on pumping and something in the system has to fail and that would be the oil filter.

This is one of the oddities of fluid dynamics in a closed system. It may seem counter intuitive but it explains what is seen in the real world. That being even with a perfectly functioning oil pump bypass the pressure reaches extraordinary high levels and burst the oil filter because of a blocked oil passage.

Lastly, If you have a dry sump oil system in addition to your internal pump and you get the dry sump pressure too high, the bypass in the internal pump will never open enough to relieve the pressure and....................wait for it....................here it comes..............you will burst your oil filter.

There will be a quiz.

Paul of MO