thx @Pegleg, you might get 1/2 an answer below..

Still cold and wet: back to MUSTANG SCIENCE!

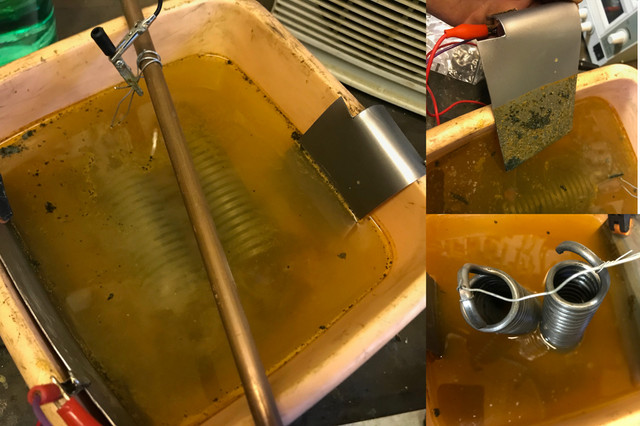

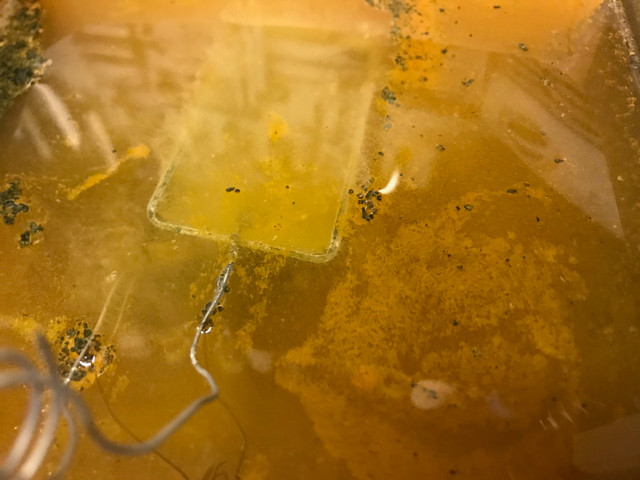

Did some experiments this week, to test alkaline solutions in scale of few cc's , aside copper working but plating way too fast and not giving me the durable result I'm after. (Tho much better than past tests with copper). Done some experiments on mixing metals, and learned the hard way how to ruin a bath that I needed this weekend

Once you have Fe or Cu or Zn in your bath, these elements plate before the Ni, and then you only get some "tiger, zebra", "pitted" results or an ugly irregular dark grey surface. (I have some of these failures outside to see if they even protect raw metal). Some say you can dummy plate at very low current to remove these, but it didn't work fast enough for my taste...

Short story: Glasses, gloves on, back to drawingboard!

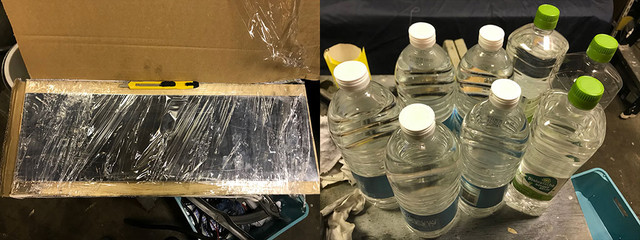

Unlike with expensive solutions, I needed 2 liters of vinegar to start over. The only problem being the time necessary to obtain a saturated enough electrolysis. at least 24 hours. Got just enough ready on time for my next victims!

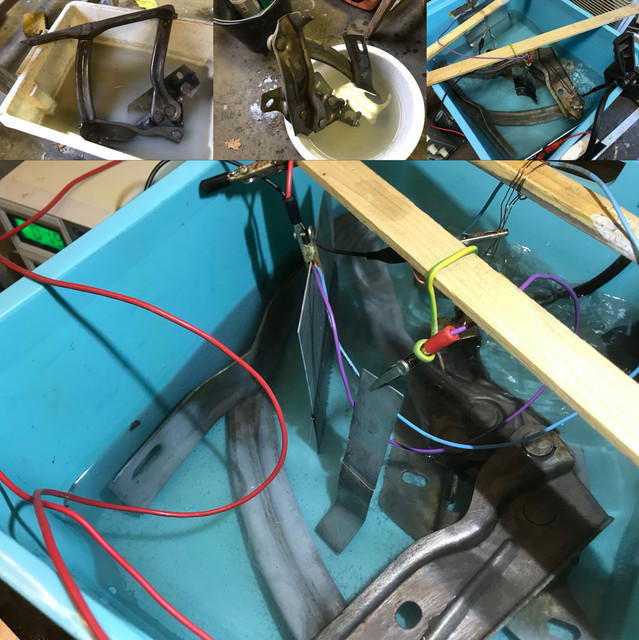

Meanwhile, during past week, I've seen that what looks clean to the eye, isn't perse true from a plating perspective, and that's exactly how I've ruined my bath last week, by dropping all kind of test bolts not really clean and having all kinds of metals on them that acted as contaminants.

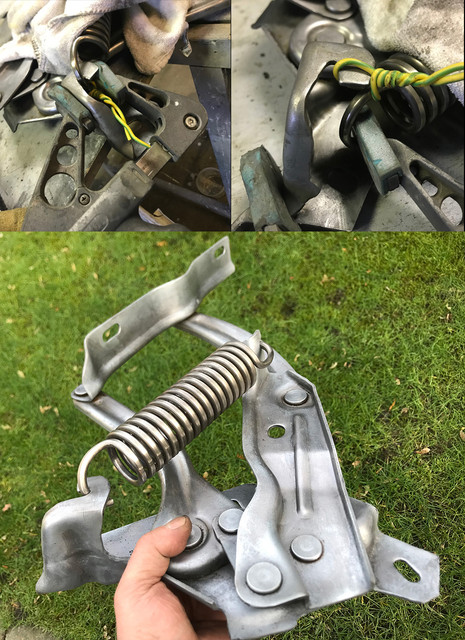

So as the hood hinges springs were next on the todo, they were previously de-rusted, but spent another 24 hours under current to remove any impurities before be placed into the bath. The solution for this is washing soda in warm water (that went cold over time as the bath heater hasn't arrived yet ). The springs came out really pristine after this electro cleaning, especially where you can't really go with your hands or tools.

While the springs were in bath, I've finished the lights, because the gasket and the plastic lens aren't really following the shape of the casing, I've taped, primed and painted the region that was exposed. Few moment later, helped with heat gun in between they were both finally done. Prolly a tad overkill.

But I was finally able to mark the valance lights as done! Yeah!

This week some of the heavy guns that I've ordered arrived!

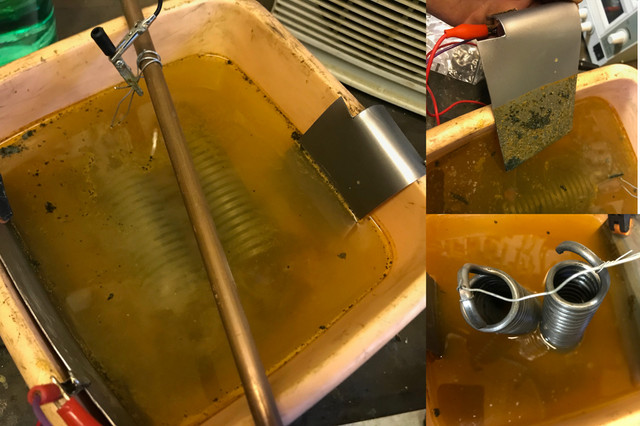

I got myself a super ultra whatever air pump for aquarium, (5 buxx) and finally got my hand on non coated pure copper wires. One would think you find this wire everywhere... nope. In all kinds of flavours, all plated/protected but not the raw copper I was after. Anyway no more hand stir, no more house wire stripping!

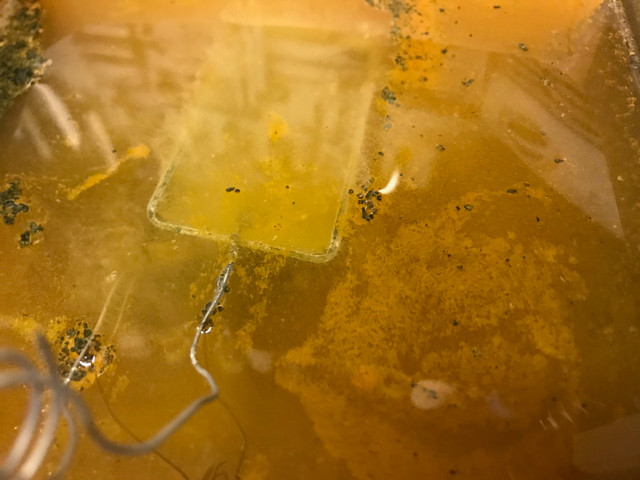

Bubbles machine in place, the first spring was set in bath after distilled water rinse, a 10 minutes hydrochloric acid session, followed by another water rinse. Not perse visible on the pict, the bath gets a nice displacement/circulation, but not enough to blow the parts away.

Funny here is that some people actually buy this cheap pump for their aquarium at home. This thing makes more noise than an old fridge!

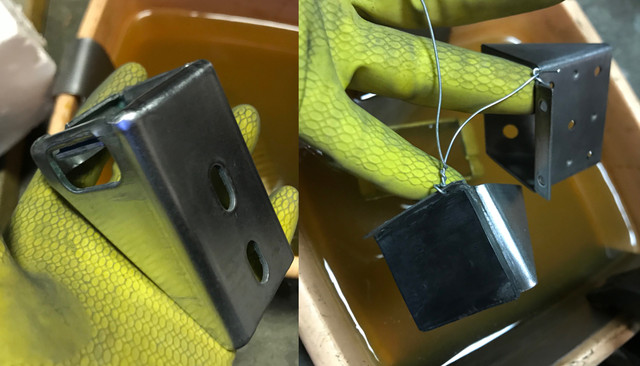

3 hours later the first one was done. very hard to photograph the diff into the bad light of my garage, and the next spring was just rinsed, but you can see the difference.

I must say it was the most difficult part to plate of my entire carriere as a plater!!! ( 3 weekends in a row)

Probably because of the shape, acting as a coil, it demanded lots of attention and did not behave as any of the parts tried before. I needed to move, rotate the part, change position of the anodes constantly to get a nice even layer of nickel.

Here's a close up of both the super clean not plated and the plated one.

@Don C, very hard to plate inside indeed, if you try the electroless kit, I'd be very curious to see how that turns out when you do yours.

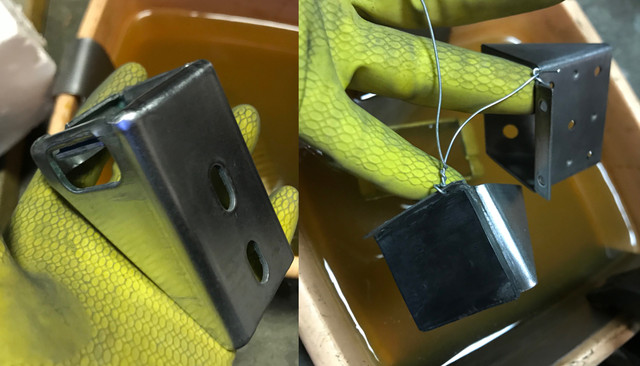

In between sessions, been busy prepping other parts, some of the 73, and also some details that will not be kept bling bling, but for some like the windshield stops that are prone to rust, I thought a protective plating before a good paint can't hurt...

Another 3.5 hours later, the second spring came out. Notice on the above pict the diffs in regions of the plating while busy. Found out that a given moment, probably once the entire surface was covered that the amps were fluctuating and going down, at this point the metal being platted becomes almost like chrome and gets deposited on the surface much much faster.

So just like the first one, during last few moments, I was rotating the part every minute and it payed off nicely. This is how it came right out the rinse bath. Once air dried and gently polished with kitchen paper, it's the most beautiful spring ever seen in my street ever!

Really pleased with the results as I did not expect to get them as nice as they turned out.

For the rest of the hinges, I'm still experimenting juices as I'd love something darker and less reflective. I hope to find out something nice for next weekend..

Too cold for me to stay longer, I've set the next soup on and should be done by tomorow.

To be continued...