Long weekend! With this misery cold weather, no hope to start body work or start any part that needs be painted right away.

As this car needs attention pretty much on everything. Among many details I'm prepping for better days, here's one of my new victims..

The hood twist locks. The visible part is made of zamac. We all know how bad looking this metal usually chromed can get, hood/fender extensions, door handles. They all get these ugly corrosion bubbles...

Repros go for 125 to 200, in real money (shipping+taxes) this means a +-250 euros at my door. I thought about asking Santa... but the guy just had rough days, so resisted and thought I'd take a closer look first.

They look pretty bad. No way I'll put these back on a restored hood. Or will I??

So decided to take a shot at them. Pretty aware I might loose my time here. I just wanted to see if parts made of that metal could be saved...

Once apart, half parts went for a bath for different durations, the rest cleaned up.

Became quickly obvious that I'm going nowhere until the chrome is removed. Hydrochloric acid is pretty much the promoted way to remove ancient chrome, tho, had to go to plan B right away as zamac doesn't like this acid very much. So instead of risking to make zamac sponges, I went over mechanical removal of the chrome. Turns out to be much harder than expected. Chrome is really tough and I needed to try different methods, combos of tools to remove it without damaging the parts.

Once I've found my "ok" tools combo to remove most of it and keep the shape undamaged, I was able to get to the casted part of pure zamac.

From there, using basic sand papers, files and a good dose of elbow grease, I was able to get to a nice level of surface finish.

I need to do a second pass with much finer polish and get the last bits of their pitted history off.

But that's the finish I've managed to give them so far. While I'm pretty happy and I see chances of totally removing the ancient corrosion.

I also know zamac will not stay long this way...

Time to cook "haute cuisine"! I've decided for 2019, to not just de-rust but also to protect for a durable finish. Electro plating here I come!

The above anodes and other details are on their way and I'll be playing the mad scientist in my garage very soon

At some point, I'll plate the above twist locks. But not before I'm confident I can get it done right, and I'll be testing on many others that do not require so much work, like brackets, bolts etc...

That's also why I will be re-polishing the details when so far, as plating doesn't fill the scratches as a thick paint primer does. Surfaces must be perfect.

@Don

Did lots of reseach in past weeks and creating own brew doesn't feel that complicated, at least for these 3 metals.

I should be able to plate most of the small stuffs I get rust free, even if the plating is not that good, the small investment done should do just fine.

If I'm really satisfied with what I'll get, I'll invest a bit more in hardware to handle bigger parts like the hood hinges and probably build some more extended bath.

Anyway, I thought I'd give it a try. I'll post some of my findings as I go... I might sing otherwise in a few weeks from now, but for now, I can't wait to get started!

On the hood hinges springs (and giving them a bit tension so something can be applied in between coils), tried a few things, none really worked, mainly because to be able to plate inside, I need the space to insert a sacrificial rod in there. However, I know what I'll need to build to make it work...

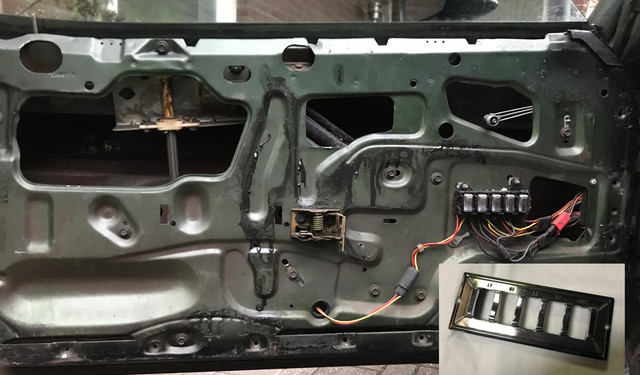

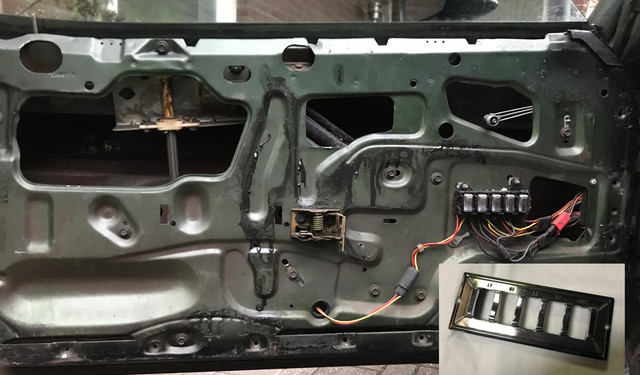

My doors need a bath, some weld work... but its too cold to think about this right now, so while I'm prepping them, taking tons of picts, I'm handling the small hardware first, like the power window bezel...

or this mirror. This mirror has the knob broken (definitely need a drilling guide for this), and needs be prep for paint later on. I wanted pull it apart but looks like its not possible to remove the cable without cutting/disconnect them somehow. From what I saw, I'll be forced to work on it with all parts still attached as I don't really feel touching the cable would be wise. Or is there a secret procedure?

After a good clean up, I've isolated the mirror support/glass and protected it from eventual shock. For now, it's under a layer of paint remover. I'm not sure much will happend due to low temp, I'll see that tomorrow...