Totally rusty (me and my muscles) from yesterday

As the fluid stayed the whole night and morning more on the front,

started today with a liquid refresh, a final moving session and let it work +-2 hours on the back while I took a breakfast and prep for another messy dirty day...

The bright orange rust was gone! Yeah!

On the left, its the liquid over staturated that drips deep orange colored saturated juice, on the left, from one of the holes of the bracket, rust is gone too, the black are deposits.

After breakfast, time for "purée de rust". Everywhere underneath the tape there was a thick layer of dissolved muddy rust and tons of rust debris.

Time to make even more mess and use high presssure water inside with kicken soap to balance the ph. Man, the sh...t that came out of it. On the right, the rag I used on the table to prevent dents on the front side and ease the manip. Cleaned it up each pressure session, and when it was full, lifted the hood to empty it. Each time a massive amount of debris came out.

Eventually, the yellow brownish water that kept coming out turned clear and when there was no more debris to be found on the rag. Next step was the drying session to prevent flash rust.

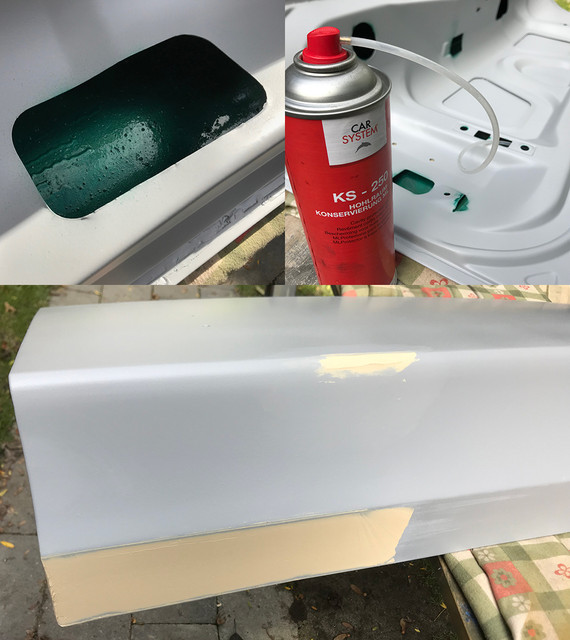

First with air, then with heat gun. Once dry, injected/sprayed pure rustico from the top. Let it rest 15, and heat gunned dry.

Somehow the pict are rose/orange colored, as I've tried make them in full sun, but the rust inside is gone. On the left, the rust left over is on top, it was under the tape, and did not get or very little exposure to the liquid, on the right, somehow burned image, due to high contrast, thats the inside at the bracket hole. the pink is an optic issue, it's grey metal color.

Once all was dry, started work on the outside, exposing the rust holes that I will be handling next week.

On this pict, you can see the inside at the latch with more real colours, there too, no more rust.

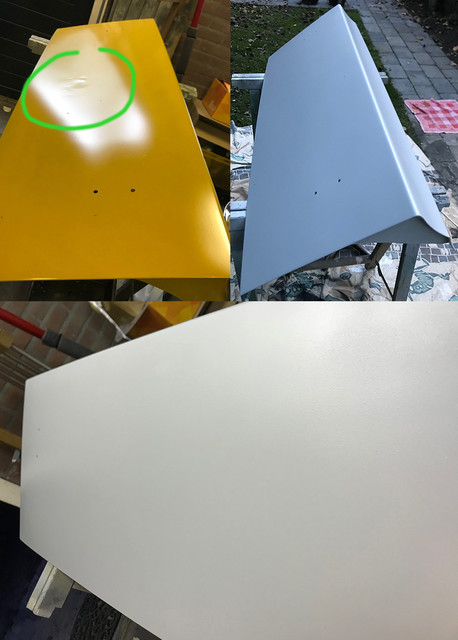

In between, it was time for a "scoop pudding", on top, the paint remover that stayed 24 hours applied. With zero force, the paint was peeling off the scoops.

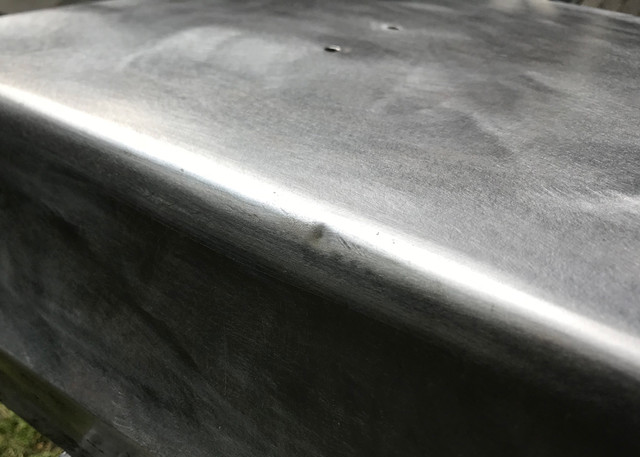

I think it took 20 minutes to get them both bare shiny. I've sanded not to be bling bling, but to provide a good base for the soon to be sprayed epoxy primer.

@Vinnie

4 liter + more than 1/2 the rustico concentrate bottle is more than agressive enough and done it twice. It could be done more but I wasn't planning to get up at nite to change fluid in the dark

Keep in mind, filling the hood is one, but then lifting/rocking it to get a wave inside that cleans up is heavy (at least for a small guy like me). I was having like 10 liters of fluid inside, it was alreally hard on my muscles, the hood is after all not the lightest.

A full dip would surely be better, but you still need to rince it, and trust me, that's really messy.

Found out (too late grrr) what I should have done, may I derust another one one day...

I should have placed the hood in huge plastic bags. Like they use for beds. tape them tight, heat gunned the plastic to fit the hood tight and only leave one hole at the latch. Say a mix of what I did and your full dip plan. I regretted not have this idea before... I would then have been able to fill it up to the neck...

Ah well, from what I saw, the most important, the side under the top of the hood is rust free, and only the most top part of the inside where I was filling could have used bit more. I need to weld there, so depending on what I will cut (and see inside), I may rebath it on that part after welding (using heat gunned plastic), but as of now, from what i saw, I don't think I will need to do it. Once protected (injection of epoxy and wax), rust will take many years before come back.

[and I may have to sand that first, somehow...]

You can forget it. No way to access anything. The spray they did, will wash off with the solution as it was likely sprayed on rust and is only near of big holes where the gun nozzle could go.

All with all, it was a very messy weekend and spend last 2 hours cleaning up everything, but glad its done now.

I will probably have to build some kind of platform for it, to move it in and out of the garage safely and without too much efforts, as placing it back in the garage alone was not that easy...

My "to be primed & painted box" has grown a lot in past weeks. So unless its raining or too cold, I might let the paint gun speak next weekend unless I return to the 73 for a change...

To be continued

@secluff

[Wish shipping expenses weren’t so insane.]

Yeah, well I have found a floor pan in Belgium, at least 800 euros cheaper than via regular USA shops, but even so 60 or 100 euros were added to let it come here. Mine is totally gone, nothing to be saved. They also import hoods, but all with all, it still would be here for 700/750 dollars. Its still lots of money vs a messy weekend. Once rust is gone, you still need to prime and paint, new or old. Plus the original hood, is made of 1mm thick metal, not the repops I saw.

[The hood on my red 71 Mach1 is in such bad shape it needs to be cooked]

Well, I bet at least 50% of the 7173 hoods have same prob. As its either considered too expensive for a repro or too messy to "cook". Most will simply close it and forget about it