Awesome Adam, wish I was there

Never got it on the carb to idle that low, 800+ yes, bellow would have ment for me be shaken crazy and have

to keep it on pedal for minutes during winter before it could keep it without dying. Curious to hear the steady "blom blo blom blom"...

Regarding higher rmp's in first seconds, My 5.0 t-bird does that too, it goes 1100, then goes gradually back to +-800.

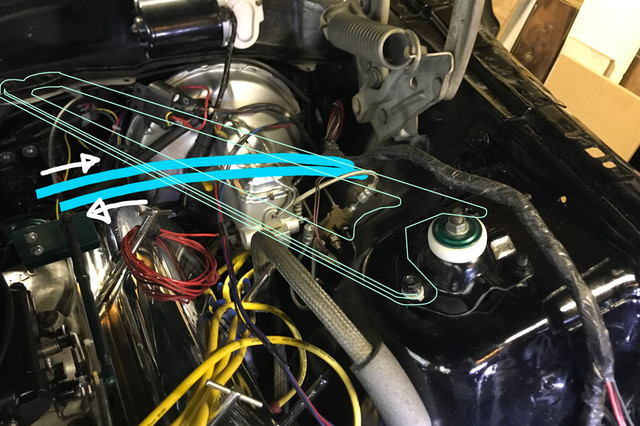

On my side, far from hearing the sweet low rpm sound, went bits further, installed the monitor inside, and routed it.

I was yesterday worried about being to short on wire length, but turned out be spot on.

Today showed me, that every new step in this install adds up to the todo...

I wasn't convinced at all about the safety of installing the two fuel lines via the tunnel already crowded by a **** load of wires.

Going bits left or right, the lines would comes too near of the exhaust heat... Plus I already know that if i would go this way,

as I plan an AOD swap, that these might be in my way soon or later and make me regret I've installed them this way.

On my 93 tbird its also coming form the side, so I've removed the front panel to see and pick the shortest and safest way.

Of course after I started remove the old line and tried pick the "ideal" location, the todo grown on me, as I need relocate

previous wirings, like my extra electric fan to clear up some space... todo++

The location should also allow me to secure them bellow the reinforcement bar (or whatever these massives brackets are named)

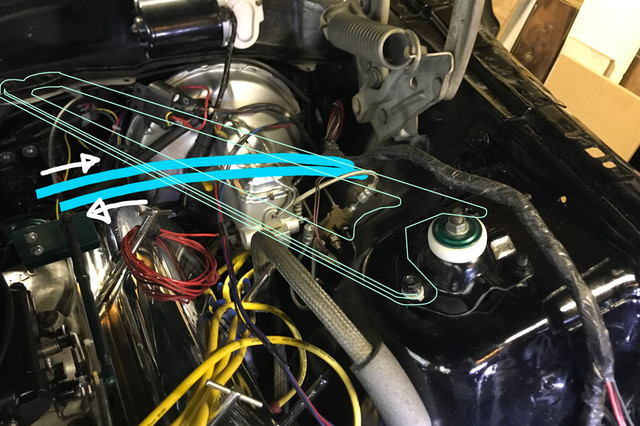

but then comes another prob in sight. Even with a nice fat grommet, once on the wheel side, they need follow some serious

curves and I really not sure I can do this with the fuels lines in one go. (I mean I could, but not sure thats the way at all)

I think 90 degrees connections would be better here.. and also may be at the bottom, where the original line takes a 90 degree turn to be aligned to the floor.

From there its straight line to rear of the car, and I haven't seen (yet) a place where it would become a problem

I even wonder if two metal lines bigger but identical in shape to the original would not even be better...

Any suggestions about eventual hardware I should use here?