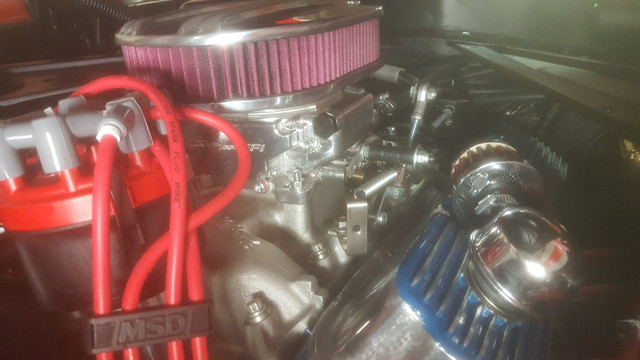

A new episode of my Sniper install:

My fuel fittings and hoses finally arrived, so time to go back to where we were...

Weather was super nice, and as its Holland, you know this is not gonna last long.

So next on the todo was the tank. In order to replace the vent cap with the (expensive) sending unit.

Before to do so, the excess fuel needed go out, so I've lowered the old fuel line to floor level,

and jacked up the car from the rear. After +- 1.5 gallon was removed, I've remove the sending unit hose, and continued at the tank

another 1/2 gallon went out. Then removed the old fuel lines fittings and the line itself.

I knew for past experience when i've repainted the tank that removing it is something that requires 4 hands.

As i'm alone working on the car, I got my extra hands by using my large floor jack with a large piece of wood and a pillow to spread the weight.

Lifted a bit, then after the straps were loose, let the hydraulics do the work, and there it was.

Note that if you never removed the tank before, I strongly suggest you oil the straps studs and nuts days before you work on the car.

These are very tricky to get out when they are rusty (and they are rusty 99% of the time).

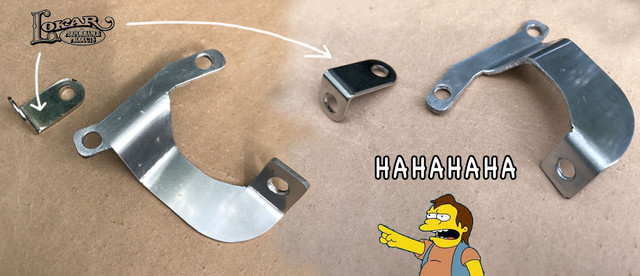

The vent cap need be tapped out gently, and I've discovered also that the sending unit doesn't fit. Noooooooo!

Unlike the pict send by Adam, the 73 tank as 3 lips evenly spread, while the sending unit has two.

So needed mutilate that poor sending unit bits more, and kept one, just to say I keep one for the $ i've spend on that stoopid tube

As the vent cap collected dirt, before clean up, I've taped it so no dirt enters the tank. Then cleanup up. primed and painted the groove, then once dry

installed the sending unit, placed the hose and painted the entire install.

Why? Because i'm far from California and anything left blank will rust in no time over here.

Reinstalling the tank is easy too, tho, take care push it bit more to rear of the car as the new nipple is slightly higher than the vent cap.

And clean/grease the straps studs/bolts, you'll be happy next time. Mine were still perfectly greased, so all that went as butter.

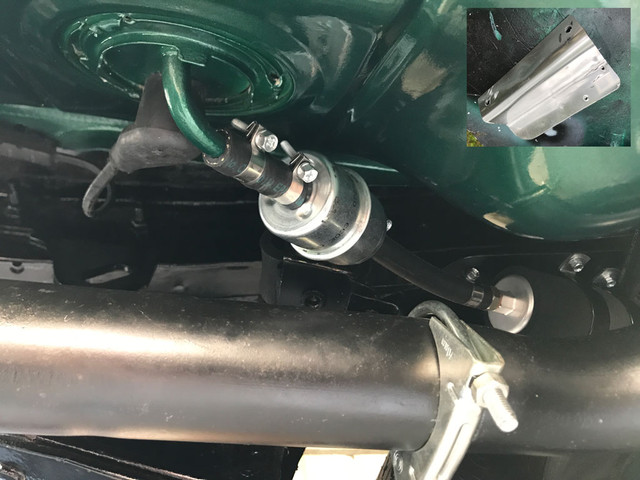

If you saw the Holley vids on sniper install, easy pizzy, you done in 5 minutes... not! It's now ideal while the tank is out to study

how and where you're gonna place the pre-filter and the pump. The space we have COULD be ok if the

sending unit nipple was pointing the other way, unfortunately, unlike the Camaro on the video, we can't place the pump

behind tank either, unless you would add a significant loop of hose as you would first need to go back toward middle of the car.

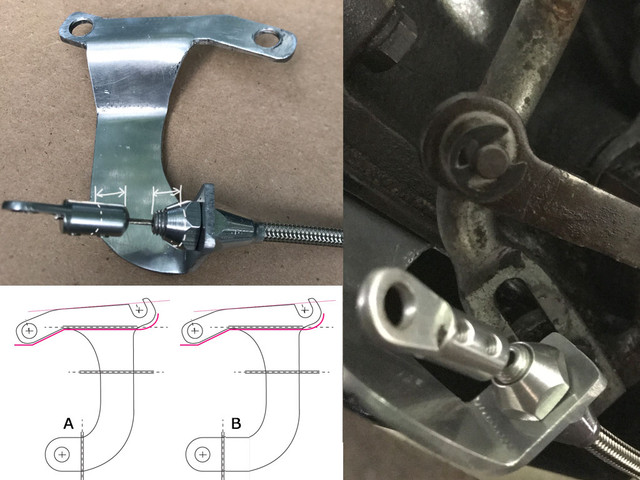

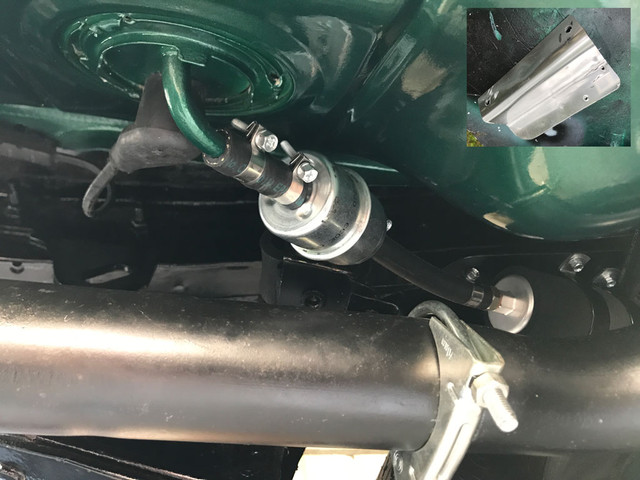

As I go by the old fuel line route, the only way to do that, is to make a bracket: yes another bracket!

On our bodies, no way to fix it on the rail without a faulty alignment with the sending unit, plus we need the pump to be

the lowest possible and near the tank.

So the bracket must lower the pump +- 2.5 inch and offer a way to align the pump. (top right on pict, before i've painted it)

Made of 3mm thick alum plate, because its 13 cms long and need two folds, you need some serious force to shape it.

If you can form it by hand, stop and pick thicker metal, it must be secure.

I'm half way there, the other side of the bracket, will allow me to complement it with a light aluminum plate

so the pump and bracket will be isolated from heat and the elements. (more picts when I'll do that part)

It will also secure the first fixation of the return line together with the feed line.

During paint drying times, drilled baie wall for the 90 degrees fuel ends (see picts from last week) and prepared the unit braided hoses.

I should be able to install these babies tomorrow.

To be continued...