I think it is great that you are jumping in and doing it yourself.

One thing I hope you did is remove all the black e-coat that comes on the repo panels. It looked like Kevin did which I recommend to everyone.

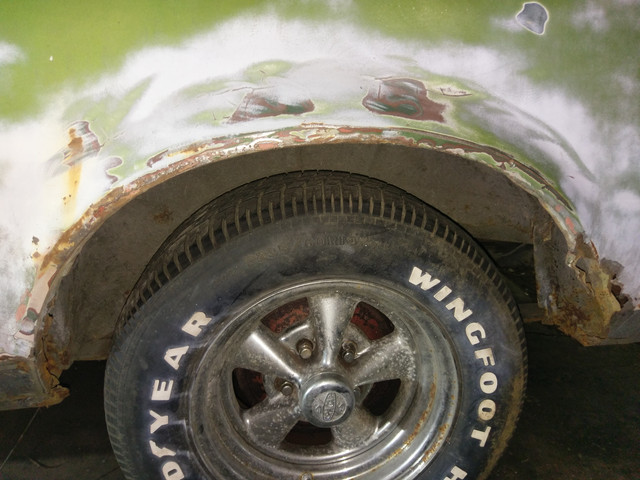

The reason is. My friend that has been doing ground up restorations since the 80's was showing me at his shop the other day. He had a guy bring his great looking car in for him to look at the paint. It had been restored by another shop about 5 years ago. There were quite a few little bumps in the paint that was once perfect. They took a razor blade and cut the paint and it just peeled off and was rusty under it.

When the repo panels are stamped sometimes they sit around and start to get surface rust on them. Then they go to e-coat and evidently their phosphate process is not very good.

My friend showed me on a hood he was working for a Camaro restore. The black e-coat was smooth and looked perfect. I stayed for a couple hours while he sanded it off with a DA and I think 80 grit paper and there were several places that had rust under the e-coat just like he said it would be. He has always sanded the e-coat off and cleaned the rust off then phosphate then epoxy primer and then polyester on all his restorations and has never had a paint job fail or return except for accident damage.

If you want the paint to last do remove the black e-coat that Taiwan puts on.

Also if you have the panels soda blasted the cleaning process for that is very intense to say the least. If you do not do it right it causes severe issues with the paint. The plastic media blast is a better solution but will not remove rust. Never sand blast exterior panels unless you want a wavy body that is trash.

Glad to see you are learning new skills and hey you got the wife in there also.

Great,

David