- Joined

- Sep 8, 2018

- Messages

- 2,046

- Reaction score

- 1,150

- Location

- Ross, Ohio

- My Car

- 71 Sportsroof Bright Red.

kcmash, I've had the same issue with my windshield wiper motor and got it resolved by adding a ground wire to the motor housing. Just a thought! I've added the wire and you've got to look really hard to even notice it!

Thanks NOT A T5! I have heard before that the ground may be a problem. The wiper motor worked when I took the car apart. I want o get it road worthy, and this is one of the few things left. Can you PM me a shot of how you did your ground? I tried loosening and re-fastening the ground on mine yesterday, but it did not help.kcmash, I've had the same issue with my windshield wiper motor and got it resolved by adding a ground wire to the motor housing. Just a thought! I've added the wire and you've got to look really hard to even notice it!

I took my wiper motor apart and cleaned all the dried up grease out of the gear box and put the Lucas Red N Tacky grease back in. I cleaned the ground strip that is under one of the mounting bolts.Thanks NOT A T5! I have heard before that the ground may be a problem. The wiper motor worked when I took the car apart. I want o get it road worthy, and this is one of the few things left. Can you PM me a shot of how you did your ground? I tried loosening and re-fastening the ground on mine yesterday, but it did not help.kcmash, I've had the same issue with my windshield wiper motor and got it resolved by adding a ground wire to the motor housing. Just a thought! I've added the wire and you've got to look really hard to even notice it!

I wan't to find a good bench test for the motor too. If I have to take it off I want to make sure it works!

kcmash

If you just take your time and get them hung in place from the top edge of the backing material you can do it. I would not do outside just because of the wind. Once you get them hung with masking tape check and double check before you pull the backing. The soap solution is only way to ever move them if a dry surface and they touch they are stuck. Longer stripes you need a helper someone to peel the backing while you hold it. Think about putting a screaming chicken on a firebird hood.Well that sucks! Anyone know how to remove the vinyl stripes? Trunk stripe went on crooked. My fault.

So I did a couple of things wrong,

1) I didn't add enough Dawn to my spray bottle for enough decal slip

2) I didn't align the trunk stripe the end cap stripes before applying the trunk stripe. Ended up wandering up higher on the drivers side of the deck lid.

3) I didn't watch the outside temperature or weather. So it got really windy and made it tough to keep the long trunk stripe wet enough to align.

So I ended up using a heat gun and patience to remove the trunk stripe. Need to order a replacement. Not sure if I should pay a bodyshop to apply from here, or see if I learned my lesson.

Kcmash

I watched that video of the Firechicken install on youtube. I thought this would be easier.If you just take your time and get them hung in place from the top edge of the backing material you can do it. I would not do outside just because of the wind. Once you get them hung with masking tape check and double check before you pull the backing. The soap solution is only way to ever move them if a dry surface and they touch they are stuck. Longer stripes you need a helper someone to peel the backing while you hold it. Think about putting a screaming chicken on a firebird hood.Well that sucks! Anyone know how to remove the vinyl stripes? Trunk stripe went on crooked. My fault.

So I did a couple of things wrong,

1) I didn't add enough Dawn to my spray bottle for enough decal slip

2) I didn't align the trunk stripe the end cap stripes before applying the trunk stripe. Ended up wandering up higher on the drivers side of the deck lid.

3) I didn't watch the outside temperature or weather. So it got really windy and made it tough to keep the long trunk stripe wet enough to align.

So I ended up using a heat gun and patience to remove the trunk stripe. Need to order a replacement. Not sure if I should pay a bodyshop to apply from here, or see if I learned my lesson.

Kcmash

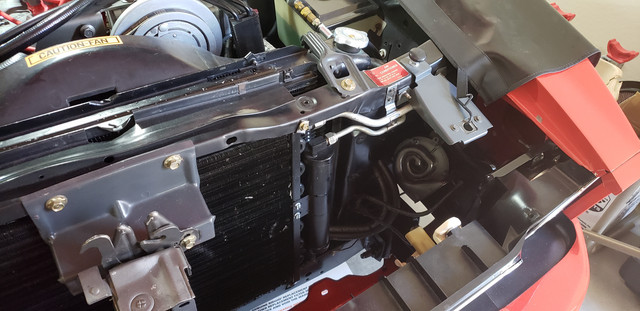

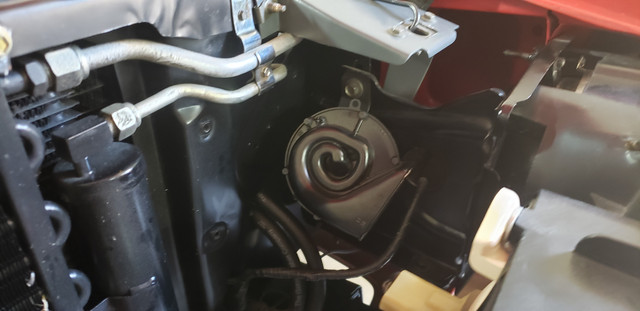

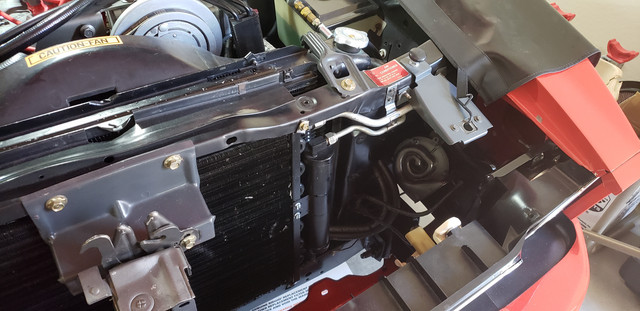

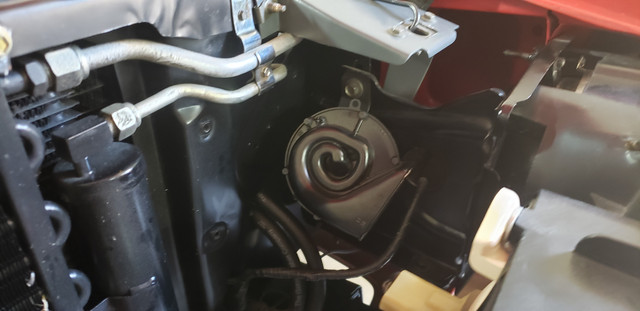

Pretty sure I'll be mounting a similar FP regulator this week. Was wondering where I might put it. You post is very timely. Thanks! I also thought about relocating the horns and moving them forward to the large open area ahead of the radiator, and getting them out of the actual engine bay entirely, but haven't looked into that deeply enough. Just an initial thought.Also mounted the horns. Had to make it work with the room I have due to hoses and fuel pressure regulator.

Good idea. There is actually enough room in the headlight boxes if needed. Out of the way there. Have to bend the mounting bracket. I was considering it but was able to make things work out.Pretty sure I'll be mounting a similar FP regulator this week. Was wondering where I might put it. You post is very timely. Thanks! I also thought about relocating the horns and moving them forward to the large open area ahead of the radiator, and getting them out of the actual engine bay entirely, but haven't looked into that deeply enough. Just an initial thought.Also mounted the horns. Had to make it work with the room I have due to hoses and fuel pressure regulator.

No. But only because I have not fussed with it. When I get a few more parts in that I'm waiting on, I'll take a look. Probably nothing major. I'll report back and close out that thread when I get it resolved.Good idea. There is actually enough room in the headlight boxes if needed. Out of the way there. Have to bend the mounting bracket. I was considering it but was able to make things work out.Pretty sure I'll be mounting a similar FP regulator this week. Was wondering where I might put it. You post is very timely. Thanks! I also thought about relocating the horns and moving them forward to the large open area ahead of the radiator, and getting them out of the actual engine bay entirely, but haven't looked into that deeply enough. Just an initial thought.Also mounted the horns. Had to make it work with the room I have due to hoses and fuel pressure regulator.

Any luck on your oil leak?

I ended up relocating the high horn up front. Was super easy. All I did was grind off the little tab and used one of the existing bolts that was already there. Where the FP regulator went, I just used the existing bolt from the horn as it was already tapped and I didn't want to misplace that bolt. So all I had to was add one more hole. Turned out well.Good idea. There is actually enough room in the headlight boxes if needed. Out of the way there. Have to bend the mounting bracket. I was considering it but was able to make things work out.Pretty sure I'll be mounting a similar FP regulator this week. Was wondering where I might put it. You post is very timely. Thanks! I also thought about relocating the horns and moving them forward to the large open area ahead of the radiator, and getting them out of the actual engine bay entirely, but haven't looked into that deeply enough. Just an initial thought.Also mounted the horns. Had to make it work with the room I have due to hoses and fuel pressure regulator.

Looks good. Glad the move worked out ok for you. I might consider moving one of mine again.I ended up relocating the high horn up front. Was super easy. All I did was grind off the little tab and used one of the existing bolts that was already there. Where the FP regulator went, I just used the existing bolt from the horn as it was already tapped and I didn't want to misplace that bolt. So all I had to was add one more hole. Turned out well.Good idea. There is actually enough room in the headlight boxes if needed. Out of the way there. Have to bend the mounting bracket. I was considering it but was able to make things work out.Pretty sure I'll be mounting a similar FP regulator this week. Was wondering where I might put it. You post is very timely. Thanks! I also thought about relocating the horns and moving them forward to the large open area ahead of the radiator, and getting them out of the actual engine bay entirely, but haven't looked into that deeply enough. Just an initial thought.