See above in red.....thx for the details Kevin.

I got enough "mess" in my garage atm (busy with electroplating), but I'd love to try this at some point.

For not too big steering/suspension/brakes components, powder coating is very attractive.

Couple of quick questions tho:

[...while you spray the powder that puts an electrical charge throughout the parts. You cant put too much on, you want to completely coat them.]

You ment too much powder or current? I guess powder. What would then happen, if you did? The current is not adjustable on this gun, just push button and pull trigger. You CAN'T put too much powder on. The metal will only take as much as it can hold. The excess fall into the tin foil lined box under the parts, to be reused later.

Once you have sprayed, how's the powder holding? I mean a little shock, wind and it all falls down or its fairly "sticking" to the surface? The powder is held on initially by the charge from the gun. You have to be very careful when loading the parts into the oven. Even a small bump and some powder can come off. But its on there pretty good if you preheated your parts. I always do a dry run with the parts hanging on the rack and plan my route to the oven, in the oven, and back to my box BEFORE I ever shoot any powder. Its better to find out then if your going to have clearance issues in the oven or with something in your way.

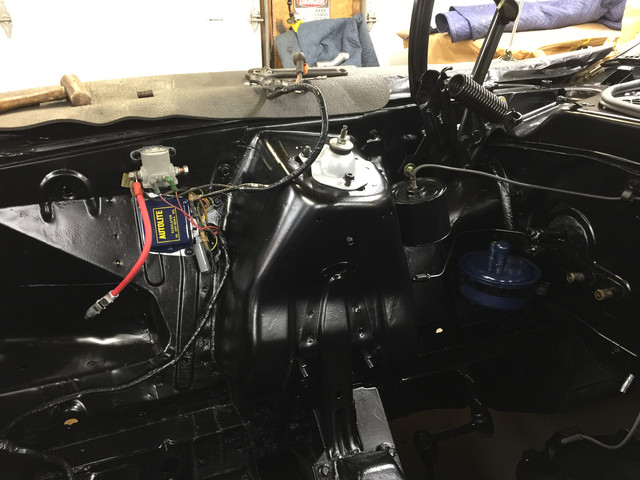

You say you can apply multiple times, how does the new layers stick? Is the powder conductive? As if not, how does the circuit works if the coating builds up and isolate the part? I hang my parts from stainless steel wire on my oven rack that is also metal. I clip the guns ground wire to the oven rack and it conducts the charge through all the parts hanging on the rack. I clean off my rack every once in a while with a flapper disc to make sure all the parts are making good contact.

Or is it that you apply the new coats while it's still bits hot and its sticky? I apply the second coat as soon as they come out of the oven after the first coat. Be careful they will be HOT, 400*. I set the rack back on my box, clip the ground wire to the rack, and proceed to shoot the second coat. Even if the conductivity isn't as good, the overall heat of the part helps the new powder stick very well. And when the parts come out of the oven after first coat, they are not sticky at all. they are fully cured and ready for use once they cool down. As you spray the second coat on you can almost watch it start to flow out over the part. its pretty cool to see. Once they come out of the oven after 2nd coat and they cool, you can put them right into service!

See pic below for ground wire on rack.

Last edited by a moderator: