- Joined

- Mar 10, 2020

- Messages

- 72

- Reaction score

- 80

- Location

- USA

- My Car

- 72 Grande, 351W, EFI, AFR heads, TKX 5spd, 9" rear, ram air

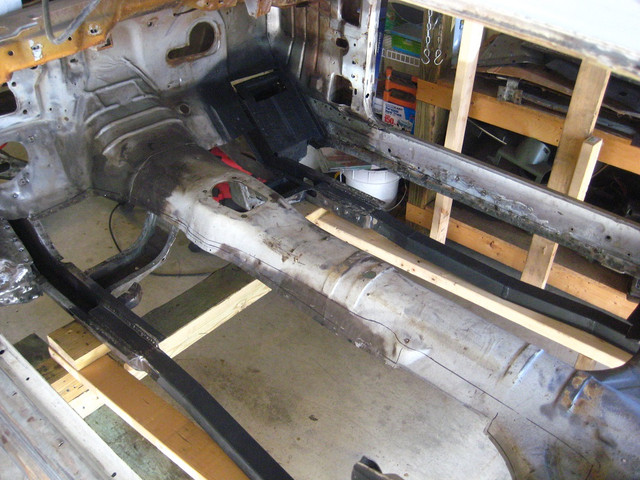

Hello all. Just wanted to introduce myself. I am kind of new of forums so please bare with me. My project is a 1972 Mustang Grande. I bought it in 2016 as a long term project car. It was a daily driver when I bought it from the seller. My intent is to rebuild it into a reliable daily driver. Something that looks cool on the outside, has lots of power under the hood, and will start every time. Although the engine and transmission seemed really good in terms of power/performance, the rest of the car needed some work. So I took the car completely apart. It now sits on a home made car dolley (4"x6" and 4"x4" lumber and industrial casters - found instructions on internet - it works very nicely) with the engine/trans and rear 9" axle in the corner of garage. The doors and front fenders are in decent shape. Just some minor rust removal/patching to do. I started at the rear of the stang (new trunk floor, lower quarter panels, rear panel, rebuilding the trunk opening rain gutter (total pain in the butt), etc. Next cleaned up the rear seat area with minor rust holes, etc. Then cut out the floor pans on driver and passenger sides. Built and installed a subframe connector from drawings found on the internet using 2" X 2" steel tubing. The new floor pans are fitted and ready to be installed. I will weld those in place after I replace the front aprons/shock towers. I then removed the upper and lower cowl and the front aprons (both sides - were very badly rusted). I considered patching but decided it was more effective to just replace both aprons (would require a ton of fabrication which I do not have the equipment for). So as of today, lower cowl is mostly spot welded in place, and both aprons have been test fitted for spot welding.

I look forward to sharing my journey and getting ideas/suggestions from you all.

I look forward to sharing my journey and getting ideas/suggestions from you all.