- Joined

- Mar 10, 2020

- Messages

- 74

- Reaction score

- 84

- Location

- USA

- My Car

- 72 Grande, 351W, EFI, AFR heads, TKX 5spd, 9" rear, ram air

Next I removed the front aprons and cowl. Both were badly rusted.

Front aprons/shock towers and cowl on.

Driver side floor pan done.

Due to COVID-19 isolation rules and me running out of shielding gas, I took a break from body work and cleanup the axle housing, ordered 3.50 gears, positrac, etc for the axle rebuild. Gear was a 2.70 on an FMX auto - I plan to put in a T5 Tremec (most likely the TKO500) and the OD ratio is good with the 3.50 rear end (for nice highway driving).

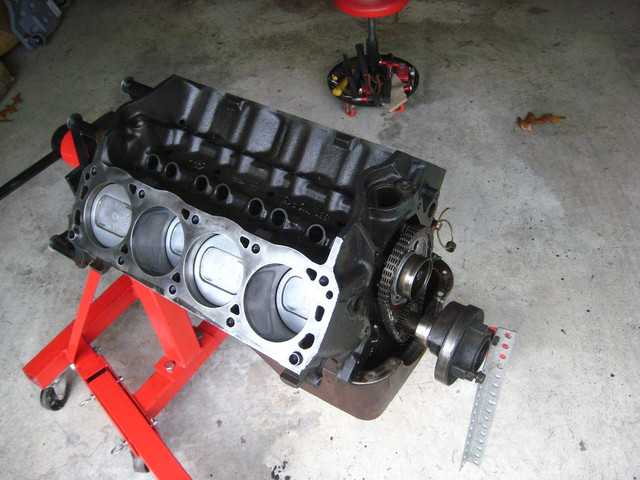

The car had a 351W. From the plate glued on the block, this is a 1972 remanufactured engine from Richmond VA. It has the D0oE-C heads which from what I read is a good stock head. It just needs to be cleaned up. Intake is an edelbrock 351W performer. From the research I have been doing, I think I will save for an edelbrock pro-flo 4 fuel injection kit. Any thoughts on that? Pic is the cylinders cleaned up. This cylinders were already bored .060 over (.060 stamped on the pistons) so no further boring will occur (from what I have read).

It has been a while so I decided to put the doors, fenders, hood (just layed on) to get a feel for what it would look like. This was motivating. It kind of resparked my energy to get this rebuild done.

Please send any thoughts or comments from what you have seen so far? Once I get some more shielding gas, I will finish the passenger floor board, tighten up any other spots that need welding, add rust inhibitor, and then seam sealer. Then maybe a coat of primer. From there the fun begins - suspension, brakes, fuel, and electrical