New whole floor pan is about $600; remove all combustibles from car before any welding... basically once this is done, the foundations for a great car are there.

Last edited by a moderator:

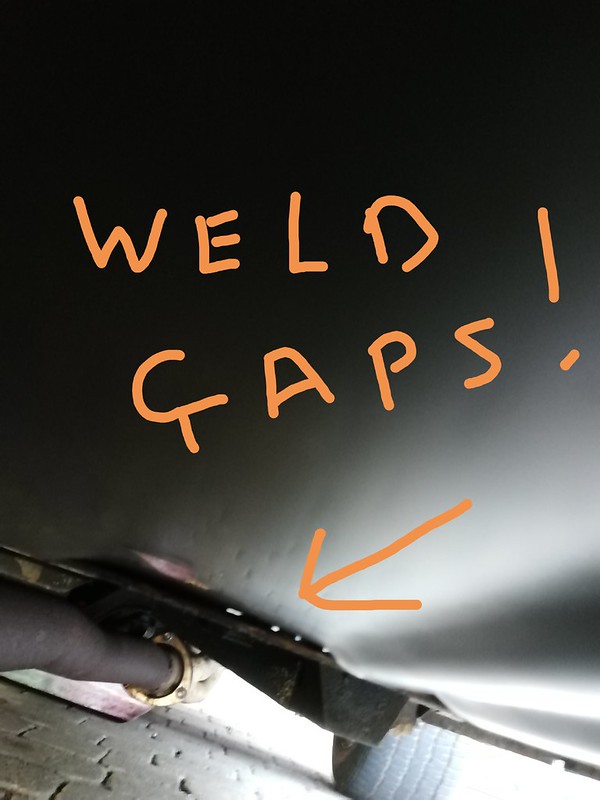

RHS Rear floor pan by Fatboy 18, on Flickr

RHS Rear floor pan by Fatboy 18, on Flickr IMG_20200415_143210 by Fatboy 18, on Flickr

IMG_20200415_143210 by Fatboy 18, on Flickr IMG_20200414_162509 by Fatboy 18, on Flickr

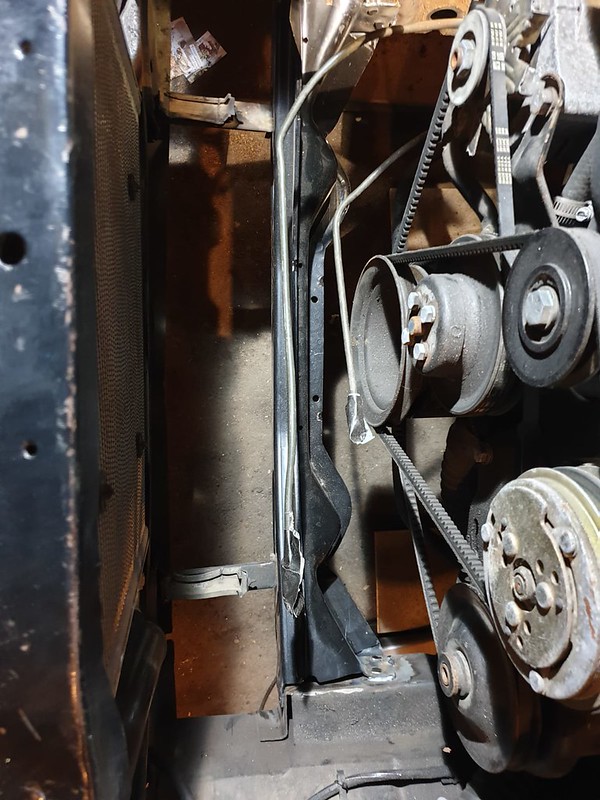

IMG_20200414_162509 by Fatboy 18, on Flickr RHS Front Crossmember welding by Fatboy 18, on Flickr

RHS Front Crossmember welding by Fatboy 18, on Flickr IMG_20200414_162532 by Fatboy 18, on Flickr

IMG_20200414_162532 by Fatboy 18, on Flickr IMG-20200412-WA0070 by Fatboy 18, on Flickr

IMG-20200412-WA0070 by Fatboy 18, on Flickr IMG_20200415_144513 by Fatboy 18, on Flickr

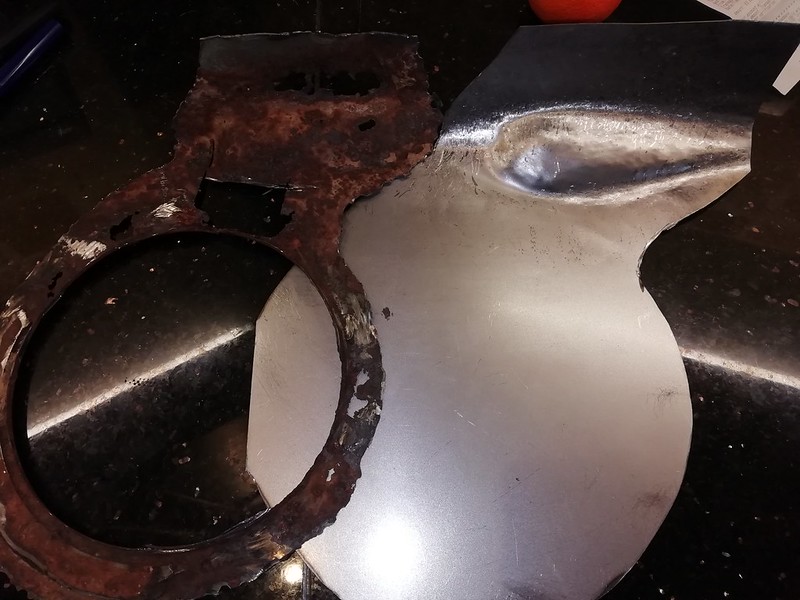

IMG_20200415_144513 by Fatboy 18, on Flickr Missing rear grille tab RHS by Fatboy 18, on Flickr

Missing rear grille tab RHS by Fatboy 18, on Flickr IMG_20200415_145301 by Fatboy 18, on Flickr

IMG_20200415_145301 by Fatboy 18, on Flickr IMG_20200414_162142 by Fatboy 18, on Flickr

IMG_20200414_162142 by Fatboy 18, on Flickr Mach 1 Grille missing fixings by Fatboy 18, on Flickr

Mach 1 Grille missing fixings by Fatboy 18, on Flickr

You're welcome. If there are other pictures you need, let us know. As for finding those, perhaps Don at OMS might be your best bet for the bracket supports.Thank's guys, Kind of what I figured on the welding:shootself:

Thanks for the pictures of the Grille support brackets, I have the long Grey ones fitted its the shorter black brackets that I need.

Holy F*** Bat Man!! Sorry to say the seller of that car really misrepresented it. I'm sure you'll get it back to where it should be in due time. We're all here to help, just ask if you need anything..... except money!

That's pretty much what I was thinkingHow are you going to tackle the missing "bowl" inlet? You could cut out the bottom and weld in a steel pet food dish.

I think the dog bowls are all stainless steel. You would have to weld stainless to non stainless :whistling:Holy F*** Bat Man!! Sorry to say the seller of that car really misrepresented it. I'm sure you'll get it back to where it should be in due time. We're all here to help, just ask if you need anything..... except money!

That's pretty much what I was thinkingHow are you going to tackle the missing "bowl" inlet? You could cut out the bottom and weld in a steel pet food dish.

Cut the hole, butt weld around new to old metal, make good the welds, weatherproof and paint then make a gasket and fit fidos bowl

The problem might be getting the bowl into the new plated cowl area?

Use R.V window and door mastic Sandwiched between the 2 steels. It will never harden and always seals well.